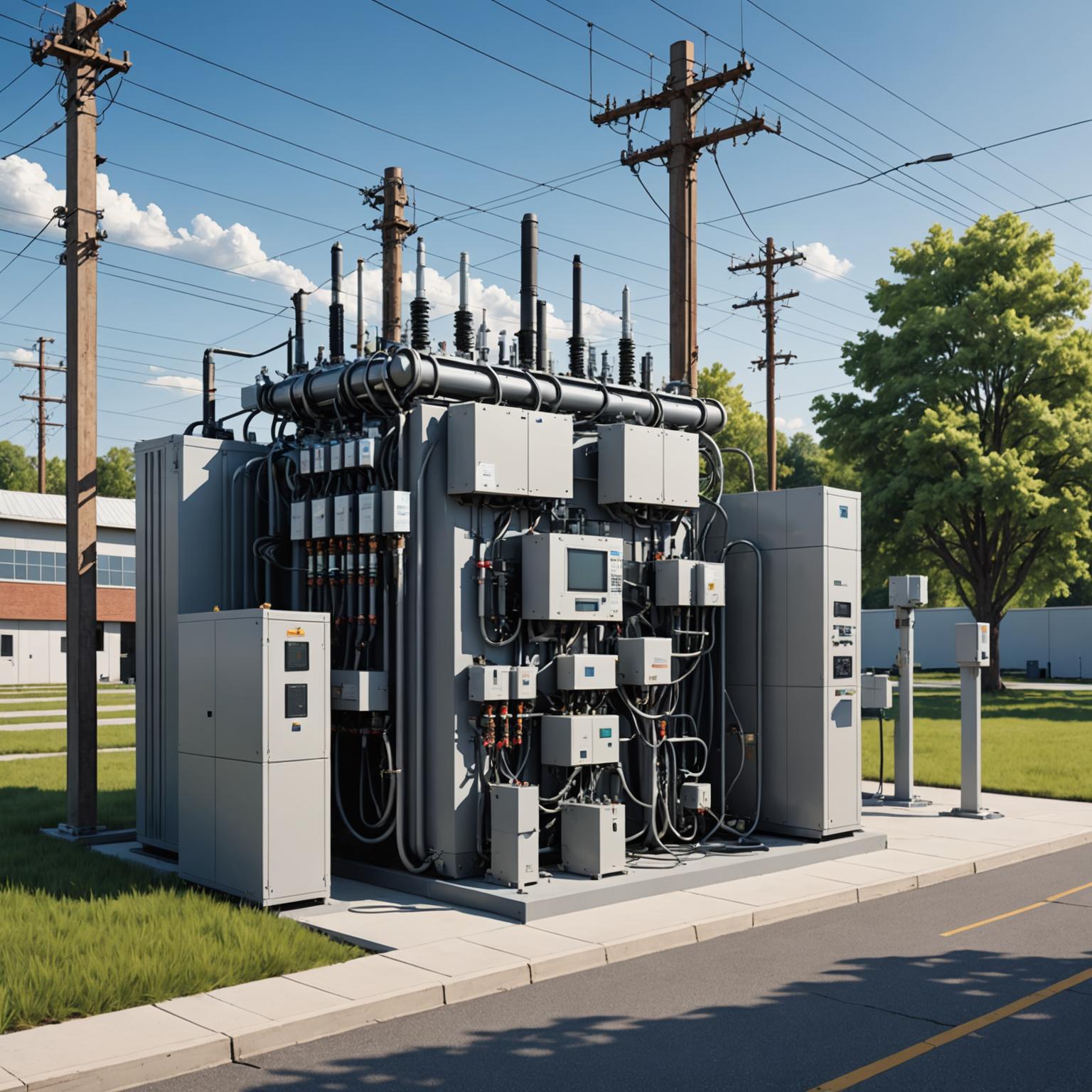

The Indispensable World of Transformer Accessories

Transformers are the silent workhorses of our electrical grids, stepping voltage up or down to ensure efficient power transmission and distribution. While the core and windings are fundamental, the safe, reliable, and efficient operation of any transformer heavily relies on a suite of crucial components known as the transformer accessor. These accessories, ranging from simple gauges to complex protective devices, are integral to modern transformer technology, playing a pivotal role in monitoring, control, and safeguarding these vital assets. Understanding their function and importance is key to appreciating the complexity and reliability of our power systems.

Defining Transformer Accessories and Their Core Functions

A transformer accessor encompasses a wide array of devices attached to or integrated within a transformer. Their primary functions include monitoring critical parameters like temperature, pressure, and oil level; protecting the transformer from faults and overloads; enabling safe operation and maintenance; and facilitating connections to the wider electrical system. Without these accessories, a transformer would be a much less reliable, less safe, and far more difficult piece of equipment to manage. They provide the necessary interfaces for human operators and automated systems to interact with and manage the transformer’s performance effectively. Innovations in accessor design continuously enhance the capabilities and lifespan of transformers, ensuring they meet the evolving demands of the power industry.

Crucial Monitoring Components: The Eyes and Ears of a Transformer

Effective monitoring is paramount for preemptive maintenance and ensuring the longevity of a transformer. Several accessories are dedicated to this task. For instance, an advanced pressure gauge is essential, particularly for oil-filled transformers, offering accurate and real-time monitoring of internal pressure. Such gauges, equipped with clear numerical calibration and responsive needle movement, are critical for pressure-tracking applications, alerting operators to potential issues like internal faults or gas buildup. Similarly, a temperature sensor probe, often a sleek and durable device, is tailored for accurate thermal readings of the oil and windings. Heat management is vital, and these probes provide the data necessary to prevent overheating, a common cause of transformer failure. An illuminated panel indicator, with its modern design and clear visibility, can also be part of the monitoring system, providing instant status alerts for various parameters on a control panel, enhancing operational awareness. For oil-filled units, components like a transparent fuel system filter, adapted for transformer oil, can be invaluable. Its clear casing allows for visual inspection, capturing impurities and maintaining the integrity of the insulating oil, which is crucial for operational efficiency and preventing dielectric breakdown. Another useful monitoring tool, especially for transformers with on-load tap changers (OLTCs), is a compact rotary counter, essential for measuring and tracking the rotational output and position of the tap changer mechanism, ensuring it operates within its designed parameters.

Ensuring Electrical Integrity and Control through Smart Accessor Design

The electrical integrity and control of a transformer are maintained by a host of specialized accessories. Insulated electrical bushings are perhaps one of the most visible and critical. These high-voltage ceramic or composite bushings are designed for maximal insulation capacity, ensuring the safe transmission of electricity from the external lines into the transformer windings and vice-versa, without compromise. Their design must prevent flashovers and ensure long-term dielectric strength. Motorized switch mechanisms also play a significant role. These robust units, often housed in metallic casings, can be part of the OLTC, allowing for voltage regulation under load, or incorporated into protective schemes like circuit breakers or disconnectors associated with the transformer. Precise control over these mechanisms is vital for grid stability and transformer protection. Furthermore, copper-based strip assemblies, precisely engineered for enhanced conduction and modular design applications, are used for internal connections and busbars. Their design ensures minimal electrical losses and reliable current paths within the transformer structure. The overall accessor design in this category focuses on safety, reliability, and efficient power flow.

Mechanical Support and Fluid Management in Transformer Design

Beyond electrical and monitoring functions, certain transformer accessories address mechanical and fluid management aspects, which are crucial for the transformer’s operational stability and longevity. For very large power transformers, a heavy-duty roller mechanism might be incorporated into the base, or used during installation, as its durable construction is ideal for load-bearing and facilitating movement of these massive units. Within the transformer, especially in those with oil circulation systems or OLTCs, precision valve systems are indispensable. Often designed with intuitive controls, such as a distinctive red handle, these valves integrate seamlessly into fluid systems, allowing for precise regulation of oil flow, sampling, draining, or refilling. Reliable valve operation is essential during maintenance and to ensure proper cooling and insulation. For connecting temperature sensors or other measurement devices, especially where flexibility and resilience are needed, a flexible metallic thermometer connector offers a reliable connection while maintaining integrity under varying operational conditions and vibrations. These components, while sometimes overlooked, contribute significantly to the holistic performance and maintainability of the transformer unit.

The Evolving Landscape of Transformer Technology and Accessories

The field of transformer technology is constantly evolving, driven by the need for greater efficiency, reliability, and integration with smart grids. This evolution extends directly to transformer accessories. We are seeing more intelligent sensors capable of providing detailed real-time data, advanced diagnostic tools integrated into accessories, and materials that offer enhanced performance and durability. For instance, digital pressure gauges and temperature sensors can now communicate directly with SCADA systems, allowing for remote monitoring and predictive maintenance algorithms. The design of bushings is improving with new composite materials that offer better pollution performance and reduced weight. Protective relays associated with transformers are becoming more sophisticated, capable of detecting incipient faults with greater accuracy. This continuous improvement in accessor design and functionality is key to extending transformer life, reducing operational costs, and enhancing grid stability. As transformer technology advances, so too will the sophistication and importance of its vital support systems.

Choosing the Right Transformer Accessories for Optimal Performance

Selecting the appropriate transformer accessor is not a trivial task; it requires careful consideration of the transformer’s type, rating, application, and operating environment. High-quality accessories contribute directly to the overall reliability and safety of the transformer. When choosing, factors such as material quality, precision engineering, adherence to international standards (like IEC or IEEE), and the manufacturer’s reputation are paramount. For instance, a robust motorized switch mechanism with a durable metallic housing speaks to its suitability for industrial-grade control systems. An advanced pressure gauge needs to demonstrate consistent accuracy. Insulated electrical bushings must have proven dielectric strength and long-term stability. Investing in superior accessor design upfront can significantly reduce the risk of premature failure, minimize downtime, and lower life-cycle costs. Our range of cutting-edge components, from precision valve systems to innovative transparent filters and temperature sensor probes, represents the pinnacle of engineering excellence, designed to ensure seamless operations and enhanced performance across various industrial applications, including the demanding environment of power transformers.

Conclusion: The Unsung Heroes of Power Systems

In conclusion, while the core and windings form the heart of a transformer, it is the comprehensive suite of transformer accessories that enables it to function effectively, safely, and reliably. From monitoring vital signs like pressure and temperature to ensuring electrical integrity with high-quality bushings and control mechanisms, each transformer accessor plays a critical role. Advances in transformer technology and accessor design continue to push the boundaries of what’s possible, leading to more efficient, intelligent, and resilient power systems. Recognizing the importance of these components and investing in high-quality options is essential for anyone involved in the specification, operation, or maintenance of transformers. They are truly the unsung heroes that keep the power flowing.