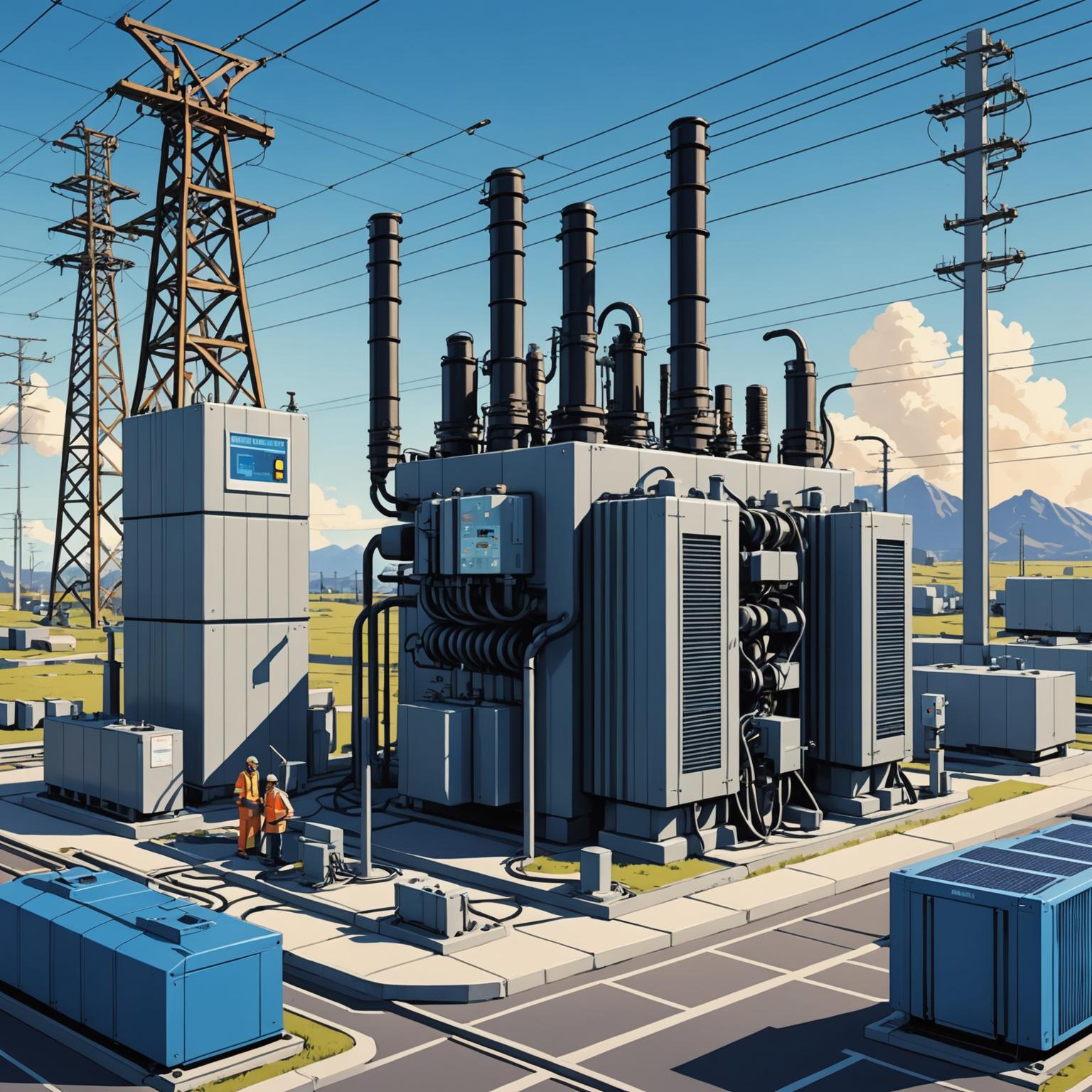

The modern electrical power system relies heavily on the efficient and reliable operation of transformers, and a key element often overlooked is the humble transformer accessor. These components, while sometimes perceived as secondary, play an absolutely critical role in ensuring the longevity, safety, and optimal performance of transformers. From simple monitoring devices to complex control systems, each transformer accessor is designed to support the main unit, contributing significantly to the overall stability and efficiency of power distribution networks. Understanding their function and importance is paramount for anyone involved in the energy sector.

The Indispensable Nature of Transformer Accessories

Transformer accessories are far more than mere add-ons; they are integral components that work in synergy with the transformer itself. Their functions range from critical safety mechanisms to vital monitoring and control systems. Without these supporting elements, transformers would be far more susceptible to failure, less efficient, and significantly more dangerous to operate and maintain. Effective accessor design ensures that these components can withstand the rigorous conditions often present in substations and industrial environments, contributing to reduced downtime and lower operational costs. The sophistication of modern transformer technology is often reflected in the advanced capabilities of its associated accessories.

Key Categories of Essential Transformer Accessories

A wide array of accessories contributes to a transformer’s operational integrity. For instance, Oil Level Indicator & Valves are fundamental for monitoring and controlling the dielectric fluid levels, which are critical for cooling and insulation. Precision-crafted indicators with transparent chambers and clear markings allow for rapid visual assessment, helping to prevent issues that could lead to significant downtime or catastrophic failure. Similarly, Pressure Gauges are indispensable for tracking the internal pressure within the transformer tank. These high-accuracy measuring instruments, often featuring an ergonomic dial face and robust casings, are designed to function reliably in high-pressure environments, providing early warnings of potentially hazardous conditions. Industries like oil & gas and electricity generation particularly rely on the durability and accuracy of these gauges for operational safety and seamless functionality.

Innovations in Accessor Design and Enhanced Functionality

The field of accessor design is continually evolving, driven by the demand for greater efficiency, reliability, and intelligence. Modern design principles incorporate advanced materials, ergonomic considerations, and smart features. Consider Temperature Sensor or Probe Assemblies; their flexible and adaptive designs allow for highly precise temperature monitoring across various points within the transformer. This data is crucial for preventing overheating and ensuring the uninterrupted operation of production lines or power systems. Another excellent example is the Rotary Actuator or Motorized Component. Robustly built and engineered for high efficiency, these devices are ideal for automated mechanical movements, such as operating on-load tap changers, which adjust the transformer’s turns ratio to regulate output voltage, thereby contributing to grid stability and operational efficiency. Their rugged design ensures they are perfect for heavy-duty industrial settings, embodying engineering excellence.

Ensuring Safety and System Longevity with Advanced Accessories

Safety and the long-term reliability of transformer installations are paramount, and specialized accessories play a crucial role in achieving these goals. Transformer Bushing & Custom Hardware are essential for ensuring safe and efficient high-voltage transmission from the transformer windings to the external circuit. Crafted with advanced materials, these bushings prevent electrical discharge and withstand significant mechanical and thermal stresses, preventing wear and tear over long operational durations. Complementing these are Ceramic Insulator Systems, which provide high-strength electrical insulation for various components. These insulators, often with a glossy finish for easy cleaning and maintenance, are designed to withstand extreme temperatures, high voltage, and challenging environmental stresses, making them essential for reliable power transmission systems. Furthermore, dedicated Safety Systems and Light Indicators, including critical alarms, serve as the first line of defense, alerting operators in real-time to potential issues or abnormal operating conditions. Their sleek designs often meet functional requirements for a modern industrial aesthetic, ensuring both operational security and a professional appearance.

The Symbiotic Relationship: Transformer Technology and Accessory Evolution

Advancements in core transformer technology directly influence the development and sophistication of associated accessories. As transformers are designed for higher voltages, increased power ratings, more compact footprints, or integration into smart grids, their accessories must evolve in tandem. For example, the push for digitized substations necessitates accessories with enhanced communication capabilities and remote monitoring features. The materials used in accessories are also constantly being improved to offer better performance under extreme thermal and electrical stresses. This symbiotic relationship ensures that the entire transformer system, including every transformer accessor, operates at peak efficiency and reliability. The demand for environmentally friendly solutions also drives innovation in accessor design, leading to the use of more sustainable materials and designs that minimize environmental impact, making systems future-proof.

Strategic Selection: Choosing the Right Transformer Accessor

Selecting the appropriate transformer accessor is a critical decision that can significantly impact the overall performance, lifespan, and safety of a transformer. It’s not merely about choosing a component that fits; it’s about investing in quality and suitability. Key factors to consider include the specific application requirements, the operating environment (temperature, humidity, corrosive elements), compatibility with existing transformer technology, and the desired level of monitoring and control. For instance, an oil level indicator for a small distribution transformer might have different specifications than one for a large power transformer in a critical substation. Prioritizing accessories from reputable manufacturers who adhere to stringent quality control standards and utilize robust materials, like those in the meticulously curated collection of industrial components designed for superior quality, ensures durability and reliability. Ultimately, the right accessories can contribute to reduced maintenance, fewer unexpected outages, and enhanced operational safety, justifying the initial investment many times over throughout the transformer’s lifecycle. Consulting with experts and reviewing detailed product specifications can guide this selection process effectively.

Conclusion: The Unsung Heroes of Power Transformation

In conclusion, while the transformer itself is the heart of power conversion and distribution, its accessories are the vital organs that ensure its healthy and sustained operation. From meticulously designed oil level indicators and robust pressure gauges to sophisticated temperature sensors and essential safety systems, each component plays an indispensable role. The ongoing advancements in accessor design and materials science, coupled with the evolution of transformer technology, promise even more intelligent, durable, and integrated solutions in the future. Investing in high-quality, well-designed transformer accessories is not an expense but a strategic decision that underpins the reliability, efficiency, and safety of our modern electrical infrastructure, ensuring that power flows consistently to where it is needed most. These unsung heroes truly enable the seamless functioning of the complex world of power engineering, placing sophistication at the heart of today’s industrial revolution.