Introduction to a Remarkable Material

Titanium wire has carved out a niche as an indispensable material across a multitude of advanced sectors, celebrated for its extraordinary blend of high strength, low density, and outstanding corrosion resistance. This versatile metal, meticulously drawn into various wire forms, delivers superior performance in demanding environments where conventional materials might falter. Its unique properties make it a cornerstone in various engineering marvels and everyday products, reflecting its growing importance in modern technology and industry. The journey of titanium from a rare element to a widely used wire product underscores significant advancements in metallurgical science and manufacturing processes.

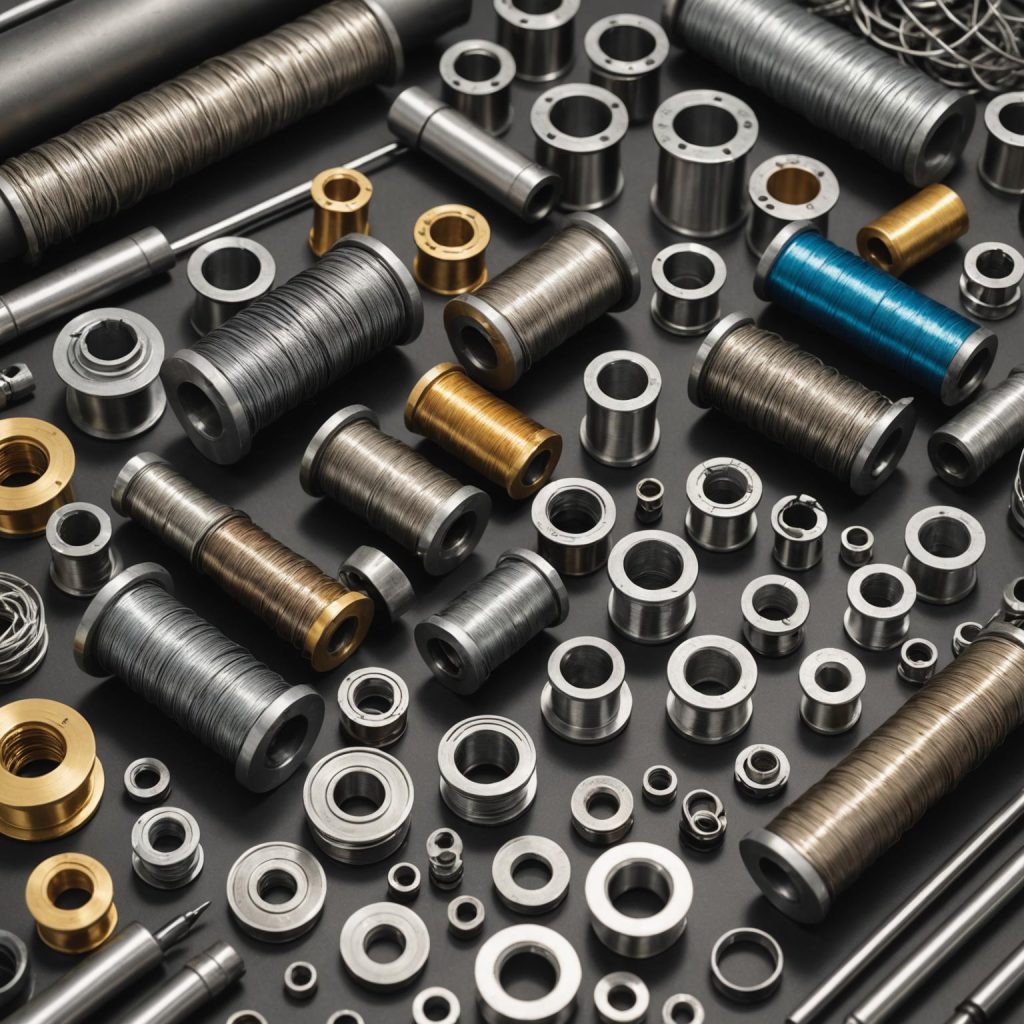

The Defining Characteristics of Titanium Wire

The allure of titanium wire stems from a compelling set of physical and chemical properties. Perhaps most famously, it boasts an exceptional strength-to-weight ratio, meaning it offers the strength of steel at roughly half the weight. This characteristic is invaluable in applications where reducing mass without compromising structural integrity is critical. Furthermore, its corrosion resistance is phenomenal, particularly against saltwater, chlorides, and many industrial acids. This resilience is due to the formation of a stable, protective oxide layer on its surface. Another key attribute is its excellent biocompatibility; titanium is non-toxic and well-tolerated by the human body, leading to its widespread use in medical implants. It is also largely non-magnetic and can maintain its properties at moderately elevated temperatures, depending on the specific alloy. These combined features make this material a preferred choice for challenging applications.

A Spectrum of Titanium Wire Applications

The diverse utility of this material is evident in the wide range of titanium wire applications. In the aerospace industry, it is used for critical components such as fasteners, springs, and structural elements due to its strength, light weight, and ability to withstand extreme temperatures and corrosive environments. The medical field heavily relies on titanium wire for surgical instruments, orthopedic pins, bone screws, dental implants, and orthodontic wires, primarily because of its biocompatibility and resistance to bodily fluids. In chemical processing plants, it’s employed in heat exchangers, piping, and vessels that handle corrosive substances. Marine applications benefit from its imperviousness to seawater, finding use in shipbuilding, offshore oil rigs, and desalination plants. Even consumer goods feature it, including high-performance sporting equipment, lightweight eyeglass frames, and durable jewelry. Its use as a welding filler material also highlights its versatility.

Guidance to Buy Titanium Wire and Select Reputable Suppliers

When you plan to buy titanium wire, several factors must be considered to ensure you acquire the right material for your specific needs. Understanding the different grades of titanium, such as commercially pure (CP) grades or alloys like Ti-6Al-4V, is crucial as each offers distinct properties. You’ll also need to specify dimensions like diameter, length, and desired form (e.g., spools, straight lengths). Certifications and mill test reports are vital for quality assurance. Choosing reliable titanium wire suppliers is equally important. Look for suppliers with a proven track record, extensive product knowledge, robust quality control systems, and a comprehensive inventory. Reputable titanium wire suppliers can provide technical support, offer various finishes, and ensure traceability of their materials. Evaluating lead times, pricing, and minimum order quantities will also be part of the procurement process to secure the best value. Taking the time to research and vet suppliers will ultimately lead to a successful purchase and project outcome.

The Evolving Landscape and Future of Titanium Wire

The field of titanium wire is not static; it continues to evolve with ongoing research and technological advancements. Scientists and engineers are constantly exploring new titanium alloys designed to offer enhanced properties, such as even greater strength, improved temperature resistance, or specific characteristics for niche applications. Manufacturing processes are also being refined to produce it more efficiently and cost-effectively, including innovations in drawing techniques and surface treatments. The rise of additive manufacturing, or 3D printing, is opening up new possibilities for utilizing this versatile wire as a feedstock material to create complex geometries with minimal waste. As industries push the boundaries of performance and sustainability, the demand for advanced materials like it is expected to grow, paving the way for its use in next-generation technologies and innovative solutions to global challenges. This ongoing development ensures that its role as a critical material will continue for the foreseeable future.