At the heart of nearly every electronic device we use daily lies a silent, foundational hero: the Printed Circuit Board, or PCB. This essential component is the green or blue board you see inside electronics, a meticulously engineered platform that houses and interconnects all the critical electronic components. It serves as the central nervous system, allowing complex circuits to function in a compact and reliable manner. The journey from a simple concept to a fully functional device is a fascinating one, involving critical stages such as innovative PCB design, rigorous testing, and precise assembly, all of which are essential to modern technology.

The Art and Science of PCB Design

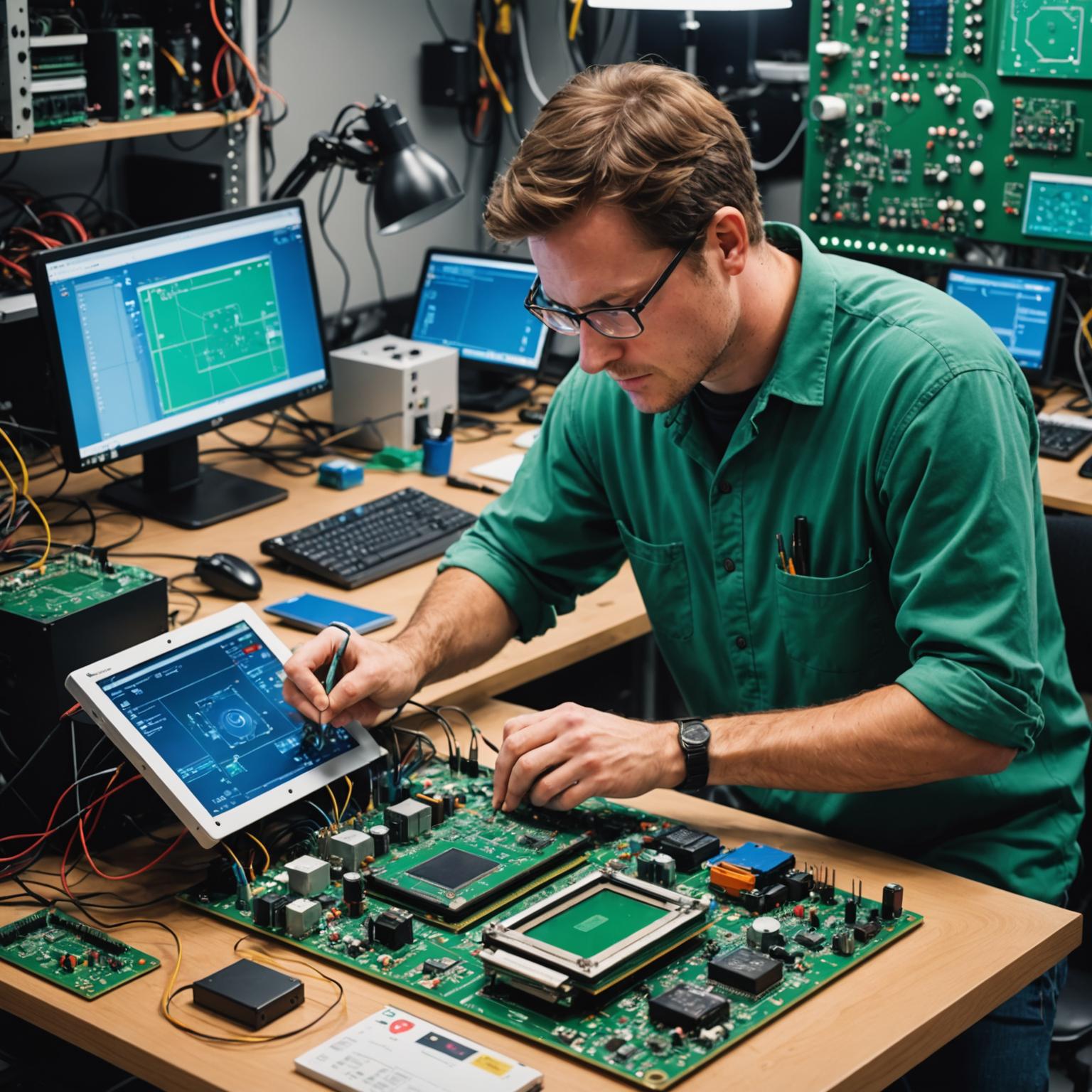

Before any circuit can come to life, it must first exist as a detailed blueprint. This is the world of PCB design, a process that blends artistic layout with stringent engineering principles. Using sophisticated computer-aided design (CAD) software, engineers map out the pathways, or traces, that will guide electricity between components. This is far more than a simple connect-the-dots exercise; designers must consider factors like signal integrity, thermal management, component spacing, and manufacturability. A well-executed design ensures the final PCB is not only functional but also efficient, reliable, and durable, forming the bedrock upon which a successful electronic product is built.

Bringing Ideas to Life with PCB Prototyping

Once the digital design is finalized, the next crucial step is PCB prototyping. This is the stage where the digital blueprint is transformed into a physical, tangible object for the first time. The primary goal of prototyping is to test and validate every aspect of the design in a real-world scenario. It allows engineers to identify and rectify any potential flaws, from incorrect connections to component incompatibilities, before committing to a costly large-scale production run. This iterative process of building, testing, and refining is indispensable, saving immense amounts of time and resources while ensuring the final product meets all performance specifications. Holding a working prototype is a milestone moment in any product’s development.

The Intricate Process of PCB Assembly Services

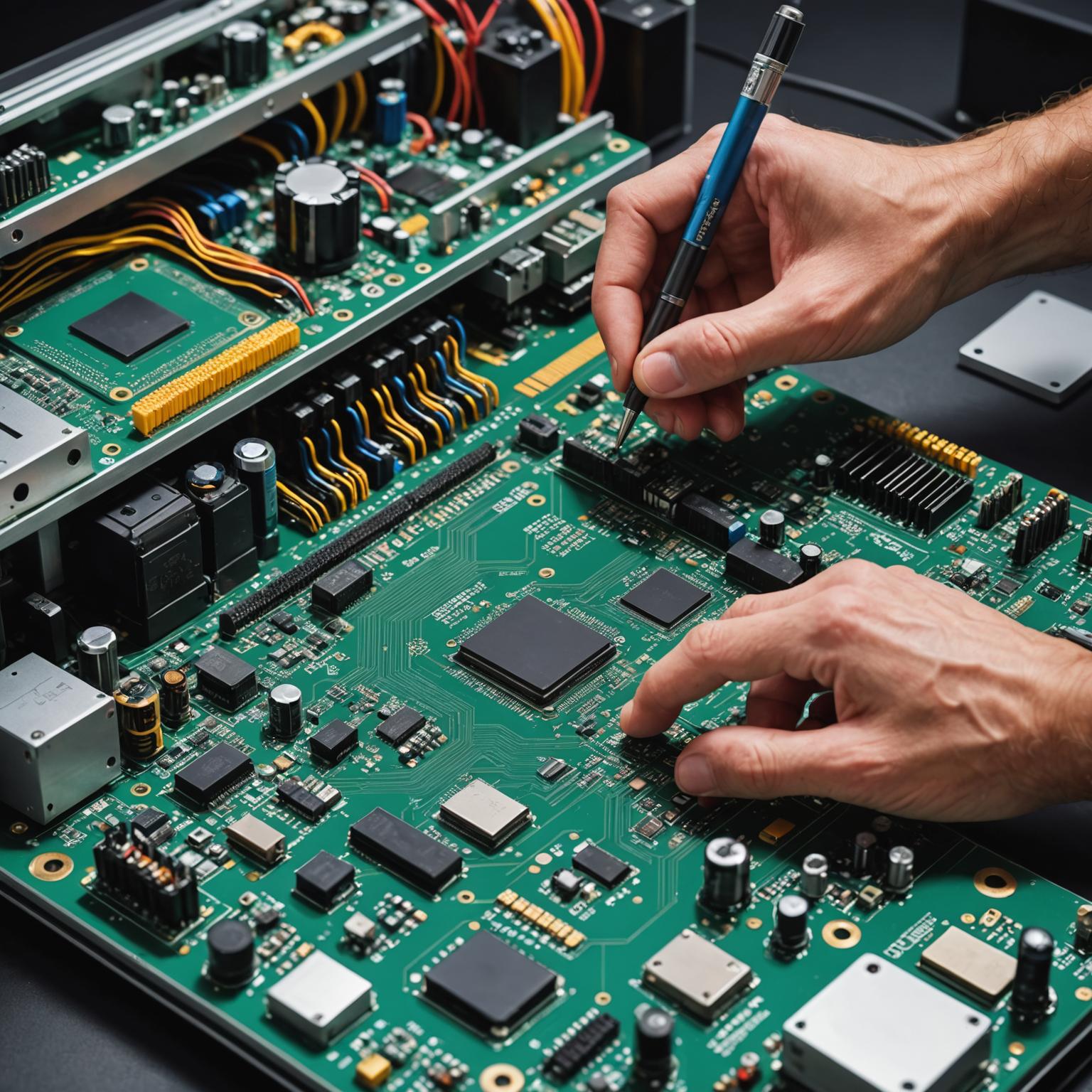

The creation of a bare board is only half the story. To make it functional, it must be populated with components like microchips, resistors, and capacitors. This intricate process is handled by professional PCB assembly services, often referred to as PCBA. Technicians use highly precise machinery for methods like Surface Mount Technology (SMT), where components are placed directly onto the board’s surface, and Thru-Hole Technology (THT), where component leads are inserted through holes. The precision and expertise offered by dedicated PCB assembly services are vital for ensuring each connection is perfect and the board functions exactly as intended, transforming an inert board into the brain of a device.

Innovation in Form: The Flexible PCB

While traditional boards are rigid, technology’s demand for smaller, lighter, and more adaptable devices has given rise to the Flexible PCB. Constructed from pliable materials like polyimide, a Flexible PCB can be bent, folded, and twisted to fit into irregularly shaped spaces where a rigid board could never go. This versatility has unlocked new possibilities in product design, making them essential for wearable technology, advanced medical implants, compact cameras, and automotive electronics. The ability to conform to the contours of a product’s casing allows for more streamlined and innovative designs, truly bending the rules of what’s possible in electronics.