Revolutionizing Surface Treatments with a PVD Coating Machine

In the world of advanced manufacturing, surface finishing technology continues to evolve at a rapid pace. At the forefront of this progression lies the PVD coating machine, a breakthrough in precision engineering and environmental sustainability. The Physical Vapor Deposition (PVD) process not only guarantees superior surface finishes but also champions eco-friendly practices, making it a pivotal force in industries that demand durability, efficiency, and innovation.

What is a PVD Coating Machine?

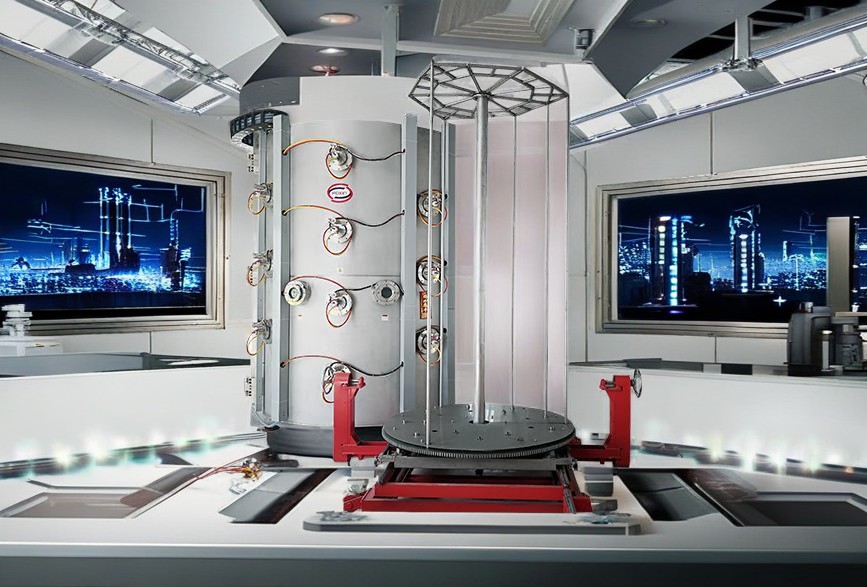

PVD coating machines are specialized systems designed to perform surface treatments through Physical Vapor Deposition. This advanced technique uses a vacuum environment to deposit thin films of material onto a substrate, resulting in coatings that enhance hardness, wear resistance, corrosion resistance, and decorative appeal. A prime example of innovation in this field is the *Circular PVD Coating Machine*, a marvel of meticulous engineering and practicality.

The Circular PVD Coating Machine embodies the future of surface finishing with its cylindrical vacuum chamber crafted from premium materials. Built for durability and energy efficiency, this chamber can sustain optimal conditions for uniform coating application, ensuring flawless results on both flat and complex surfaces. This level of consistency addresses high manufacturing demands, whether for automotive components, decorative products, optical applications, or cutting tools.

Eco-Friendly Efficiency

A key advantage of the PVD coating process is its environmentally-conscious design. Unlike traditional coating methods that often involve harsh chemicals and generate liquid waste, PVD coating operates without chemical pollutants or hazardous byproducts. This makes it an attractive solution for industries striving to implement sustainable manufacturing practices without compromising performance or quality.

The *Circular PVD Coating Machine* takes sustainability to new heights. Its cutting-edge cathode and power systems are optimized to ensure energy-efficient operation while adhering to rigorous environmental standards. For industries transitioning to greener technologies, this machine is a vital asset for reducing their environmental footprint.

Advanced Technology for Superior Results

The technology behind the *Circular PVD Coating Machine* is as impressive as its applications. At its core lies an advanced modular cathode setup, coupled with a sophisticated power distribution system. These elements work in harmony to create a highly consistent coating process, guaranteeing superior surface finishes every time.

One standout feature is the machine’s rotating base. With a high-precision turntable mechanism, it ensures even weight distribution, enabling 360-degree uniform application on parts of all shapes and sizes. This enhances coating consistency and significantly boosts productivity—an indispensable advantage in today’s competitive manufacturing landscape. Furthermore, the robust yet aesthetically pleasing red-and-black base provides structural support and ease of handling during loading and unloading.

Versatile Applications Across Industries

The versatility of PVD coating machines is unparalleled, and the *Circular PVD Coating Machine* is no exception. Its capabilities extend far beyond basic applications, enabling enhancements like multi-layer coatings, increased hardness, improved wear resistance, and decorative finishes. These features make it an invaluable tool for industries seeking to push the boundaries of innovation.

In the automotive sector, PVD coatings are used to improve the durability and aesthetics of components such as gears, engine parts, and wheels. Cutting tools benefit from reinforced hardness and wear resistance, which leads to longer service life and superior performance. Similarly, decorative elements, such as jewelry or high-end consumer goods, gain an immaculate, corrosion-resistant finish that ensures both beauty and longevity.

Optical applications also benefit vastly from PVD coatings, where anti-reflective or enhanced reflective properties are crucial. The ability to produce such customized coatings establishes PVD coating machines as essential equipment in the field of advanced optics and photonics.

A Blend of Innovation and Elegance

The *Circular PVD Coating Machine* exemplifies the seamless integration of innovative technology and elegant design. Its sleek exterior and user-friendly operation make it a delight to incorporate into any production setup. Beyond its aesthetic appeal, its robust performance and unwavering reliability elevate the machine from being merely functional equipment to a benchmark of industrial excellence.

In addition to its cutting-edge performance, this machine represents a commitment to sustainability, operational efficiency, and technological advancement. It empowers manufacturers to meet the highest production standards while keeping pace with modern industry’s growing focus on environmental responsibility.

Why Invest in a PVD Coating Machine?

PVD coating machines are more than just tools—they’re strategic investments that offer significant long-term benefits. By delivering precise, durable, and environmentally-friendly coatings, these machines help manufacturers stay ahead of the competition. Moreover, the reduction of waste, maintenance needs, and energy consumption leads to substantial cost savings over time.

Specifically, the *Circular PVD Coating Machine* offers unmatched performance through features like optimized modular cathodes, uniform coating distribution, and versatile application capabilities. Companies investing in this technology will not only enhance the quality and durability of their products but also align themselves with the future of sustainable manufacturing.

Conclusion

In a world where precision, efficiency, and environmental responsibility are paramount, the PVD coating machine stands as a pillar of progress. By combining cutting-edge technology, unmatched reliability, and sustainable operation, the *Circular PVD Coating Machine* exemplifies the best of what modern engineering has to offer.

Whether for automotive components, cutting tools, decorative pieces, or optical applications, this machine redefines the standards for surface finishing. With its innovative design and versatile functionality, it is a triumph of craftsmanship and a testament to what is possible when technology meets purpose. Investing in a PVD coating machine is not just a step forward—it is a leap into the future of advanced manufacturing and sustainable production.