The seamless and efficient operation of power systems heavily relies on the robust performance of transformers, and integral to this performance is a suite of specialized components collectively known as the transformer accessor. These accessories, often unsung heroes, play critical roles in monitoring, protection, control, and maintenance, ensuring that transformers function reliably and safely throughout their operational lifespan. From the largest power transformers in transmission substations to smaller distribution units, the right selection and quality of each transformer accessor directly impact overall grid stability and the longevity of the transformer itself. Understanding these components is therefore crucial for anyone involved in the energy sector.

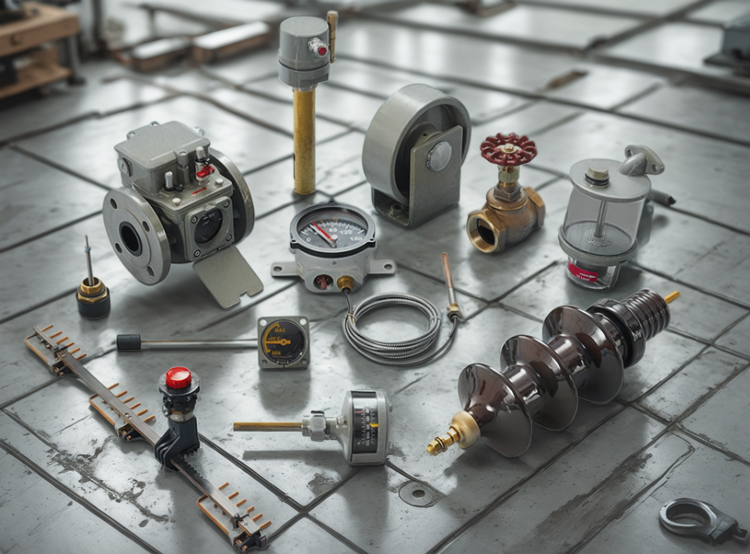

A critical function of any group of accessories is to provide constant monitoring of the transformer’s operational status. Transformers, especially those that are oil-filled, generate significant heat and internal pressure variations during load changes. Therefore, instruments like analog pressure gauges and precise temperature probes are indispensable. These devices offer real-time data, allowing operators to detect anomalies such as overheating or excessive pressure build-up, which could indicate internal faults or overloading conditions. Early detection through reliable monitoring accessories enables preventative maintenance, averting catastrophic failures and costly downtime. The evolution of transformer technology has also led to more sophisticated sensors that can integrate with SCADA systems, providing remote visibility and diagnostic capabilities, further enhancing the protective umbrella these accessories provide.

Electrical integrity is paramount in high-voltage environments where transformers operate. High-quality insulators, such as the robust dark-brown ceramic types mentioned in typical component showcases, are essential. These serve as specific accessory components, often in the form of bushings, providing insulated pathways for electrical conductors to pass into and out of the earthed transformer tank. They must withstand high electrical stresses and varying environmental conditions without breakdown. Complementing insulators, surge protection systems, including surge arresters, are vital for safeguarding transformers from transient overvoltages caused by lightning strikes or switching operations. These protective devices divert excess surge energy to the ground, preventing damage to the transformer’s insulation and internal windings. The development of advanced materials and testing methods within transformer technology continually improves the reliability and performance of these crucial protective accessories.

Beyond monitoring and electrical protection, many transformer components are mechanical in nature, facilitating operational control and maintenance. Advanced gear mechanisms, often found in rotary gearboxes, are prime examples. These are critical components in On-Load Tap Changers (OLTCs), which allow for voltage regulation while the transformer is energized and supplying load. The precision and durability of these gear mechanisms are crucial for the reliable operation of the tap changer, a complex transformer accessor in itself. Furthermore, industrial-grade valves, often featuring heavy-duty construction and ergonomic handles, play a significant role in fluid management. They are used for oil filling, draining, sampling, and isolating sections of the cooling system, ensuring that maintenance can be performed safely and efficiently. The thoughtful accessor design of these mechanical components emphasizes longevity and ease of operation even in harsh industrial environments.

Lubrication and sealing are fundamental to sustaining the smooth operation of a transformer’s internal moving parts, such as those within tap changers, and also for maintaining the integrity of the main tank. Accessories like glass lubrication containers for auxiliary systems offer a clear advantage by allowing visual monitoring of lubricant levels and condition. This transparency is a simple yet effective feature that contributes to proactive maintenance, ensuring that mechanisms remain well-lubricated to prevent wear and tear. The accessor design of these containers, focusing on sturdy build and secure sealing, prevents contamination and leakage, which is vital for both environmental protection and sustained performance. The choice of materials for seals and gaskets within various accessories, including inspection hatches and terminal boxes, is also a critical aspect of accessor design. These materials must ensure compatibility with transformer oils and demonstrate resilience to temperature fluctuations and aging, thereby maintaining the integrity of the entire transformer system over extended periods and preventing costly oil leaks or moisture ingress.

Modern power systems increasingly rely on automation and sophisticated control, and transformers are no exception. Sleek switchgear panel components, often equipped with intuitive controls like push-buttons and indicators, are integral to this ecosystem. While not always directly mounted on the transformer itself, these components form part of the broader suite of accessories that enable automated operation, protection, and remote control of transformer functions. They interface with protection relays, monitoring systems, and control logic to manage circuit breakers, tap changers, and cooling systems. The integration of such advanced switchgear signifies a leap in transformer technology, moving towards “smart” transformers that can adapt to grid conditions, communicate their status, and even self-diagnose certain issues. The robust design of these panels, ensuring clear interfaces and reliable operation, is crucial for the safety and efficiency of automated substations. This synergy ensures optimal performance and adherence to stringent safety standards in high-tech electrical setups.

Maintaining the intricate systems within and around a transformer necessitates a range of specialized measuring tools. These compact and meticulously calibrated instruments, while perhaps not permanently affixed, are essential accessories for inspection, testing, and commissioning. They allow technicians to accurately assess various operational parameters, from insulation resistance and winding continuity to oil quality through Dissolved Gas Analysis (DGA) sampling points, which are themselves a type of fixed accessory. The precision of these tools is paramount, as accurate measurements form the basis for informed maintenance decisions, directly impacting the transformer’s reliability and operational lifespan. The ongoing advancements in metrology contribute to the development of more accurate, portable, and user-friendly diagnostic tools, which are indispensable for managing the health of critical transformer assets. This focus on precision underpins the broader efforts in advancing overall system technology towards greater efficiency and predictive maintenance strategies.

The development and selection of transformer accessories are not isolated processes but are intrinsically linked to the broader evolution of transformer systems. Innovations in material science, for instance, lead to more durable insulators that can withstand higher electrical and mechanical stresses, or more resilient gasket materials that improve sealing and reduce oil leaks. Similarly, advancements in sensor technology enable more comprehensive and accurate real-time monitoring, feeding data into sophisticated diagnostic algorithms. The design philosophy for these components increasingly emphasizes modularity for easier replacement, enhanced safety features to protect personnel and equipment, and compatibility with digital communication protocols for integration into smart grid architectures. This holistic approach ensures that each accessory, no matter how small, contributes effectively to the overall goals of reliability, efficiency, and longevity of the transformer. The demand for higher power densities, reduced environmental impact, and improved grid stability continually drives innovation in both the core transformer unit and its supporting accessories, creating a cycle of continuous improvement. Manufacturers are constantly researching methods to enhance heat dissipation through more effective radiators and cooling fans, reduce noise levels with better enclosure designs or core construction, and improve the fault ride-through capability of transformers, and accessories often play a pivotal role in achieving these upgrades.

In conclusion, the diverse array of components that fall under the umbrella of transformer accessories are far more than mere add-ons; they are fundamental to the safe, reliable, and efficient operation of transformers, which are themselves the backbone of electrical power systems. From the crucial monitoring provided by pressure and temperature gauges to the protective functions of insulators and surge arresters, and the operational control afforded by tap changer mechanisms and valves, each accessory performs a vital task. The ongoing advancements in their design and their integration with evolving technologies underscore their importance. High-quality, well-maintained accessories not only extend the life of the transformer but also contribute significantly to grid stability, operational safety, and the economic efficiency of power delivery. Therefore, a thorough understanding and careful selection of these components are essential for ensuring the optimal performance and longevity of these critical assets within our energy infrastructure. Investing in superior accessories is an investment in the resilience and future-readiness of the entire power grid.

评价

Clear filters目前还没有评价