The world of architecture has always been a story of ambition clashing with the constraints of material science. For centuries, designers dreamed of structures that could soar to new heights, span vast distances, and wear facades as intricate as a painter’s canvas. I remember my early days as an architect, poring over blueprints for a high-rise tower, feeling the immense pressure of every choice. The central challenge was a familiar one: how to create a visually stunning, durable exterior without adding prohibitive weight to the core structure. It was during this project that my team and I rediscovered a material that felt less like a building component and more like a piece of the future: the Aluminum honeycomb panel. It promised to solve the age-old paradox of strength versus weight, opening a new chapter in our design story.

Our initial skepticism gave way to fascination as we delved into the engineering behind these panels. The concept, inspired by the natural perfection of a beehive’s honeycomb, was deceptively simple yet profoundly effective. A core of hexagonal aluminum cells is sandwiched between two thin aluminum sheets. This structure creates an incredibly rigid and strong panel while being composed mostly of air. This is the secret behind what makes them such effective lightweight aluminum panels. For our tower project, this meant we could design an expansive, seamless facade without demanding a Herculean effort from the building’s foundation. The logistical benefits were immediately apparent; transporting and lifting these panels on-site required less heavy machinery and fewer man-hours, translating into significant cost and time savings that thrilled our client.

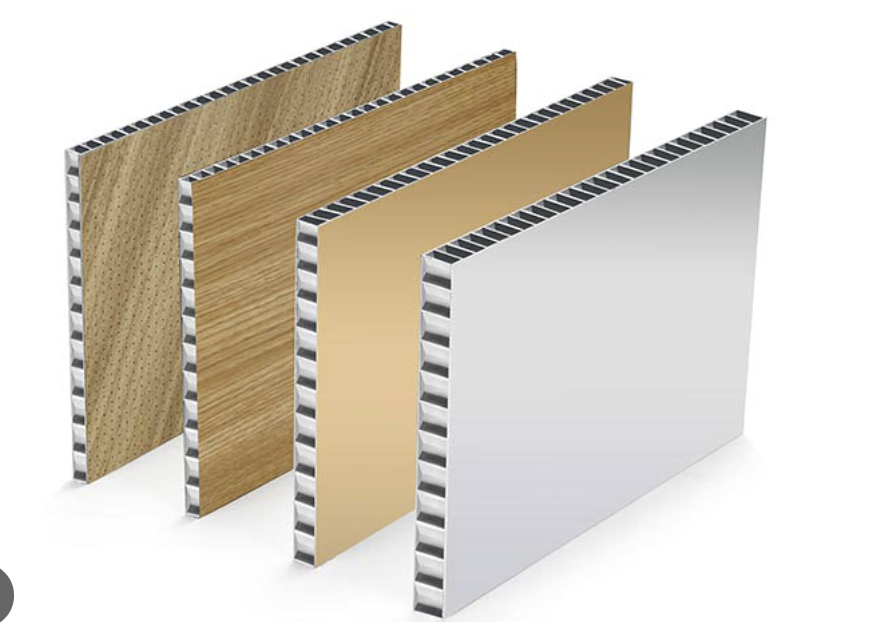

The functional advantages were clear, but the aesthetic possibilities truly ignited our creative spirit. We were no longer limited to heavy, monolithic materials. The product sheets we reviewed showcased a breathtaking array of finishes. We could clad one section in a warm, convincing wood grain texture for a biophilic touch, transition to a sleek, brushed metallic finish for a futuristic gleam, and use classic matte white panels to create a sense of clean, modern elegance. This versatility meant the building’s exterior could tell a story, with different textures and colors defining functional zones and creating visual interest. The Aluminum honeycomb panel was not just a protective skin; it was our new canvas, allowing for a level of design freedom we had previously only dreamed of.

As our confidence in the material grew, we began exploring the vast range of honeycomb panel applications beyond just exterior facades. For the tower’s grand lobby, we used large-format panels with a polished stone finish for the ceiling, creating a dramatic, monolithic look without the immense weight and complex installation of real stone slabs. In the executive office suites, we used them as sleek, sound-dampening partition walls. This exploration opened our eyes to their use in other industries. We learned about their role in high-speed rail, where reducing weight is critical for achieving higher speeds and greater energy efficiency. We saw them in marine applications, used to build bulkheads and furniture on luxury yachts where strength and moisture resistance are paramount. The sheer breadth of honeycomb panel applications demonstrated that this was a solution for nearly any design challenge that required a combination of strength, lightness, and aesthetic refinement.

During the construction phase, the narrative of efficiency continued. Our installation team, accustomed to working with much heavier materials, was amazed at the ease of handling the lightweight aluminum panels. The precision-engineered panels fit together seamlessly, accelerating the timeline for enclosing the building. But our choice was about more than just a smooth construction process; it was about the building’s entire lifecycle. These panels offered superior durability against weathering, UV radiation, and moisture, ensuring the facade would retain its beauty for decades with minimal maintenance. Furthermore, their excellent fire resistance provided a critical layer of safety, a non-negotiable aspect of modern construction. It was a long-term investment in quality, safety, and lasting aesthetic value.

Perhaps the most compelling part of this material’s story, especially in today’s environmentally-conscious world, is its commitment to sustainability. As a firm dedicated to green building principles, this was a major factor in our decision. The core design of the Aluminum honeycomb panel is inherently resource-efficient, using a minimal amount of material to achieve maximum structural integrity. Moreover, aluminum is infinitely recyclable without any loss of quality. Choosing these panels helped us contribute to a circular economy, reduce the project’s overall carbon footprint, and achieve a higher LEED certification. This wasn’t just about building a beautiful tower; it was about building a responsible one.

Looking back, that project was a turning point. It taught us that the right material doesn’t just fulfill a function; it transforms possibilities. From the initial design challenge to the final, gleaming structure, the journey with these lightweight aluminum panels was one of discovery and innovation. They allowed us to build not just bigger and faster, but smarter and more beautifully. The story of our tower became a testament to how modern engineering can bring ambitious architectural visions to life, proving that with the right tools, the only real limit is our own imagination.

评价

Clear filters目前还没有评价