I remember the initial sketches for the “Aura Tower” project like it was yesterday. The client envisioned a skyscraper that didn’t just scrape the sky but seemed to float within it—a structure of immense scale yet ethereal lightness. The challenge was immense. Traditional materials like concrete or solid steel would require such a massive foundational and structural support system that the project’s budget and aesthetic would be compromised. We were stumped, caught between the client’s brilliant vision and the physical limitations of construction materials. It was during a late-night research session, surrounded by material samples, that I first truly encountered the Aluminum honeycomb panel. It wasn’t just another option; it felt like the answer we had been desperately searching for.

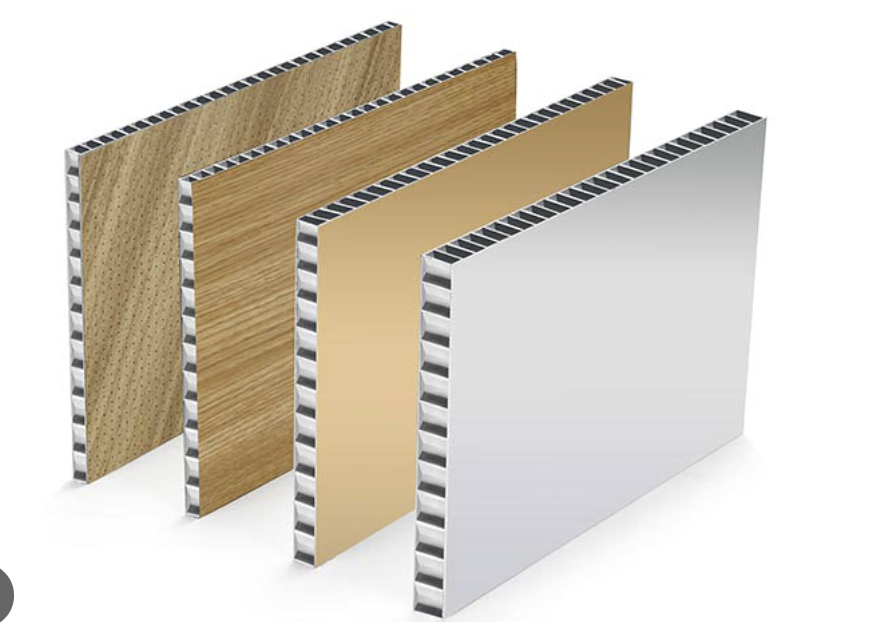

At first glance, it seemed too simple. A core of hexagonal aluminum cells, just like a bee’s honeycomb, bonded between two thin aluminum sheets. But the genius, I soon learned, was in this very simplicity, a design perfected by nature over millennia. The hexagonal structure distributes forces with incredible efficiency, creating a panel with a strength-to-weight ratio that is nothing short of revolutionary. We ordered a sample, and holding it in my hands was a revelation. It was so astonishingly light, yet when we subjected it to stress tests in our lab, its rigidity was comparable to solid plates many times its weight and thickness. This discovery was the turning point for the Aura Tower. We had found our material, a key component in a new generation of lightweight aluminum panels that could make our architectural dream a reality.

Suddenly, the project’s logistics became feasible. The reduced weight of the facade meant we could slim down the building’s core structural frame, saving millions in steel and concrete. Transportation costs plummeted, as we could ship more square footage of paneling per truckload. On-site, the installation process was dramatically accelerated. A smaller crew, with less heavy machinery, could lift and fix the large panels into place. The cascade of benefits was undeniable, turning a project teetering on the edge of impossibility into a model of efficiency. These lightweight aluminum panels weren’t just a building material; they were a comprehensive solution that positively impacted the project’s timeline, budget, and even on-site safety. It was a paradigm shift in how we approached large-scale construction.

The practical advantages were only half of the story. As an architect, aesthetics are the language I speak, and the Aluminum honeycomb panel offered a vast and expressive vocabulary. For the Aura Tower’s exterior, we chose a sleek, metallic silver finish. We wanted the building to reflect the changing colors of the sky, to shimmer in the sunlight and glow with a soft luminescence at dusk. The panels provided a perfectly flat, seamless surface that achieved this effect flawlessly. But the versatility didn’t end there. For the building’s grand lobby and executive suites, we explored other finishes. A warm, convincing wood grain finish was used for feature walls, creating an inviting and organic atmosphere that beautifully contrasted with the building’s modern exterior. In the penthouse restaurant, we used panels with a matte gold finish for the ceiling, adding a touch of opulence and luxury. The range of potential honeycomb panel applications began to expand in my mind, from facades and interiors to ceilings, furniture, and even artistic installations.

Our client was also deeply committed to environmental sustainability, aiming for the highest LEED certification. Here again, the Aluminum honeycomb panel proved to be the perfect choice. The panels themselves are manufactured from highly recyclable aluminum, contributing to a circular economy in building materials. Their closed-cell honeycomb core also provides excellent thermal and acoustic insulation. This inherent property meant we could reduce the building’s energy consumption for heating and cooling, a significant factor in its long-term operational costs and environmental footprint. When we presented this data to the client, showing how the material choice contributed to both the building’s aesthetic and its green credentials, their excitement was palpable. The material had aligned every stakeholder’s goals.

The completed Aura Tower now stands as a landmark in the city’s skyline. It is a testament to what is possible when innovative design meets advanced material science. Visitors often comment on its seemingly weightless appearance, how it interacts with the light and the atmosphere around it. They are always shocked to learn that the beautiful, strong facade is made of such a light material. The building is not only an architectural success but also a high-performing, energy-efficient structure that will stand strong for generations, thanks to the panel’s resistance to corrosion and moisture. My experience with the Aura Tower project fundamentally changed my perspective. I no longer see just a list of materials; I see a spectrum of possibilities. The journey taught me that the right material doesn’t just build a structure; it unleashes creativity and redefines what we believe is possible in the world of design and construction.

评价

Clear filters目前还没有评价