The Evolution of Auto Parts

The world of auto parts is constantly evolving to meet the demands of modern vehicles and the ever-changing automotive industry. As new technology and materials emerge, the auto parts industry adapts by introducing components that enhance the performance, efficiency, and reliability of vehicles. Key to this evolution is the introduction of precision-engineered components, such as our aluminum CNC machined parts, which play a critical role in revolutionizing mechanical systems.

Understanding Auto Parts and Their Suppliers

Auto parts are integral to the operation of any vehicle, from the simplest engine components to complex, high-performance assemblies. The market for auto parts is vast, encompassing everything from the smallest screw to elaborate engine blocks and electronic modules. At the heart of this market are the auto parts suppliers, who play a crucial role in providing the essential components needed to keep vehicles running smoothly.

Suppliers must continually source and supply durable, reliable parts that meet stringent quality standards. A supplier’s reputation is built on their ability to deliver products that enhance vehicle performance while adhering to manufacturing excellence.

The Role of Precision-Engineered Components

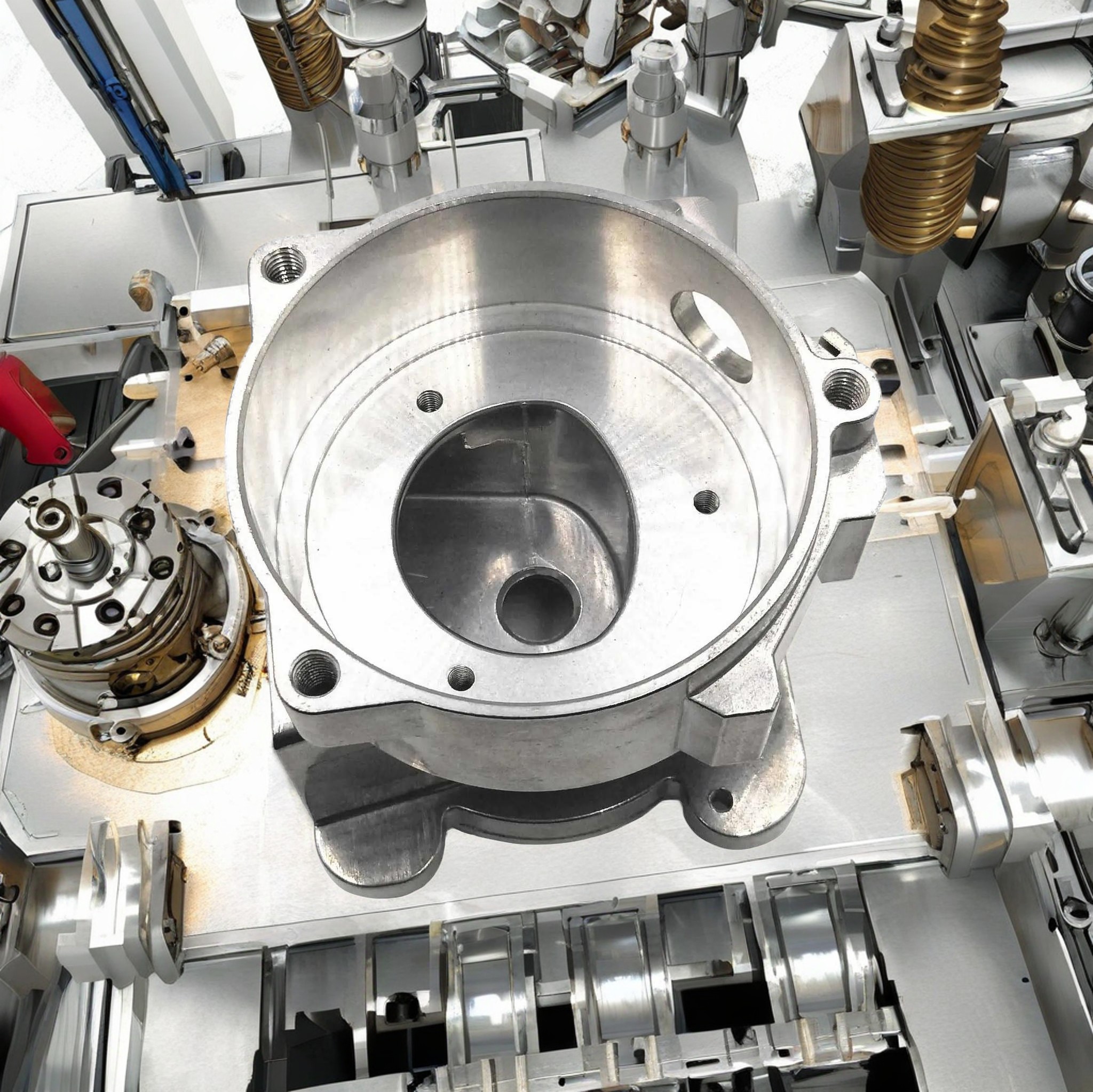

In the highly competitive automotive industry, precision-engineered components can make all the difference. Take, for instance, our aluminum CNC machined components. These parts are designed with an eye for detail, ensuring that they meet the highest standards of performance and quality. The use of high-grade aluminum provides a unique combination of durability and lightweight properties, enabling these parts to withstand high-stakes operations without compromising efficiency.

Design and Performance Attributes

The sophisticated design of CNC machined components incorporates multiple drilled ports and threaded holes, offering a remarkable level of versatility and adaptability in complex assemblies. This ensures that the component can integrate seamlessly into a variety of applications, reducing friction and enhancing the overall performance of mechanical systems. Every curvature and edge is carefully crafted to ensure a perfect fit, contributing to the component’s resilience and unmatched durability.

One of the standout features of these components is their smooth, polished surface. This not only reduces wear and tear over time but also imparts a sleek, modern aesthetic to any machinery it becomes a part of. This characteristic makes it an ideal choice for industries that prioritize both function and form in their mechanical systems.

The Importance of Durable Auto Parts

In a market as expansive and varied as auto parts, durability is a critical attribute. Auto parts must endure a great deal of stress and pressure, operating under a variety of environmental conditions. The resilience of a part translates directly to the reliability of the vehicle as a whole. Our aluminum CNC machined components stand out for their robust construction and impeccable finish, setting a new benchmark for durability in the industry.

The Future of the Auto Parts Industry

As automotive technology continues to advance, the demand for sophisticated, high-performance components is likely to increase. Suppliers and manufacturers will need to prioritize innovation, precision, and engineering excellence to stay ahead in the market. The introduction of components like the precision-engineered aluminum CNC machined parts represents a forward-thinking approach to modern auto parts manufacturing, setting the stage for future developments.

In conclusion, the auto parts industry is at the cusp of significant transformation, driven by the need for high-quality, durable components. Companies that invest in precision engineering and innovative design are well-positioned to lead the market. By prioritizing quality and embracing advanced manufacturing techniques, these companies can meet the evolving demands of the automotive industry, ensuring their relevance and success in the years to come.