In the demanding world of modern industry, where uptime is currency and precision is paramount, the silent heroes are often the components that deliver consistent, reliable power. At the heart of countless automated systems, manufacturing lines, and critical infrastructure lies the Industrial switching power supply, a device engineered to be the unwavering heartbeat of complex machinery. These units are not merely accessories; they are foundational elements that ensure everything from sensitive electronics to heavy-duty motors operates flawlessly, day in and day out. Their design philosophy centers on efficiency, durability, and safety, providing the clean and stable energy that powers progress in today’s fast-paced technological landscape.

The Heart of Efficiency: Understanding the Switching Power Supply

A switching power supply is a marvel of modern electronics, representing a significant leap forward from older, bulkier linear power supplies. Its primary function is to convert electrical power efficiently. Specifically, it acts as an AC to DC power supply, taking the alternating current (AC) from a wall outlet and transforming it into the stable direct current (DC) that most electronic components require to operate. The magic lies in its method. By rapidly switching the current on and off at a high frequency, it can perform this conversion with minimal energy loss, typically achieving efficiencies of 80% or higher. This high efficiency means less energy is wasted as heat, which not only saves on electricity costs but also allows the power supply to be built in a much more compact and lightweight form factor. This reduction in size and heat generation makes it an ideal choice for densely packed control cabinets and machinery where space and thermal management are critical considerations.

A Closer Look at Superior Design and Construction

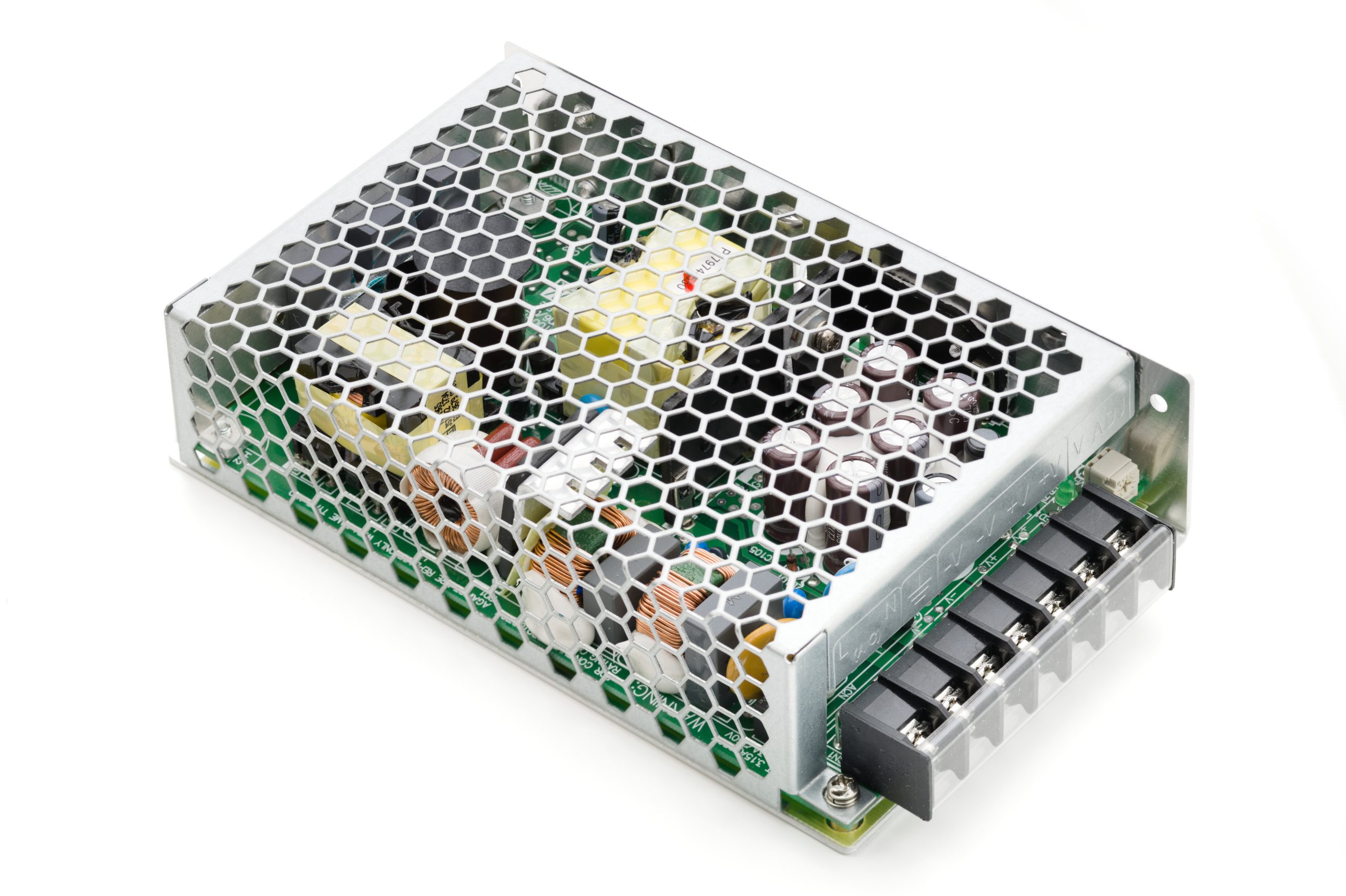

When you first behold a top-tier Industrial switching power supply, its thoughtful engineering is immediately apparent. The exterior is often a robust metal enclosure, serving as a steadfast shield against the physical rigors of an industrial environment, from accidental impacts to ambient vibrations. Many feature a distinctive hexagonal honeycomb ventilation design. This isn’t a mere aesthetic choice; it is a masterclass in passive thermal management. The pattern is meticulously calculated to maximize open surface area, creating a natural and unimpeded pathway for air to flow. This constant circulation effectively dissipates the heat generated during operation, ensuring the internal components remain at optimal temperatures even under sustained, heavy workloads. This intelligent cooling design is crucial for longevity, preventing premature component failure and guaranteeing the unit can deliver its full potential without faltering, thus becoming a silent guardian against performance degradation caused by overheating.

Inside the Unit: Premium Components for Unwavering Reliability

Beneath the protective metal casing lies the true core of its performance: a high-efficiency circuit board populated with premium-grade components, each selected for its contribution to stability and endurance. Glistening, tightly wound copper coils work diligently to manage the flow of energy, while oversized, high-quality capacitors stand ready to smooth out any fluctuations in the electrical current. This meticulous selection of parts ensures the output is incredibly stable, with minimal electrical noise or ‘ripple.’ For sensitive industrial equipment, like programmable logic controllers (PLCs) or precision sensors, this clean power is non-negotiable. A fluctuating or noisy power source can lead to erratic behavior, data errors, or even permanent damage. This commitment to using superior internal elements means the switching power supply delivers a constant, reliable stream of energy, safeguarding the expensive equipment it powers and ensuring the integrity of the entire operation.

Designed for Versatility and Ease of Use

The practical application of any component is just as important as its internal specifications. A truly effective power supply is one that integrates seamlessly into a wide array of systems. This is why these units are designed with a multi-terminal output block, providing a clear and organized point of connection for various loads. Each terminal is distinctly labeled for positive, negative, and ground connections, simplifying the installation process and reducing the chance of wiring errors, even in the most complex control panels. This ease of integration is further enhanced by its adaptability. Supporting wide-range voltage inputs, a single unit can be deployed across different regions and electrical grids without modification. This versatility makes it a go-to solution for a vast spectrum of industries, from powering sophisticated automation systems and robotic arms to driving large-scale LED lighting installations and communication equipment. Its role as a universal AC to DC power supply cements its value as a flexible and indispensable tool for engineers and system integrators.

Unyielding Safety in Demanding Environments

In any industrial setting, safety is the highest priority. A power supply failure can have consequences ranging from costly downtime to hazardous electrical events. Recognizing this, a premier Industrial switching power supply is engineered with a comprehensive suite of built-in safety protections. These are not optional add-ons but are integral to the device’s core design. Short-circuit protection instantly cuts power if an electrical short is detected, preventing catastrophic damage and potential fire hazards. Overload protection monitors the current being drawn by the connected equipment; if it exceeds the unit’s rated capacity, the power supply will safely shut down to protect both itself and the load. Furthermore, over-voltage protection guards against dangerous voltage spikes that could otherwise destroy sensitive electronics. This multi-layered safety net provides complete peace of mind, ensuring compliance with modern safety standards and creating a secure operating environment for both personnel and machinery.