The Indispensable Role of Modern Cooling Solutions

In the landscape of modern industry, precise temperature control is not just a luxury; it is a fundamental pillar of productivity, quality control, and operational safety. At the heart of this critical function lies the Industrial Chiller, a sophisticated piece of equipment designed to remove heat from processes and machinery, ensuring they operate within optimal temperature ranges. For any business looking to enhance its manufacturing or processing capabilities, understanding the value of these systems is the first step, and fortunately, there are many high-quality industrial chillers for sale that can meet diverse operational needs.

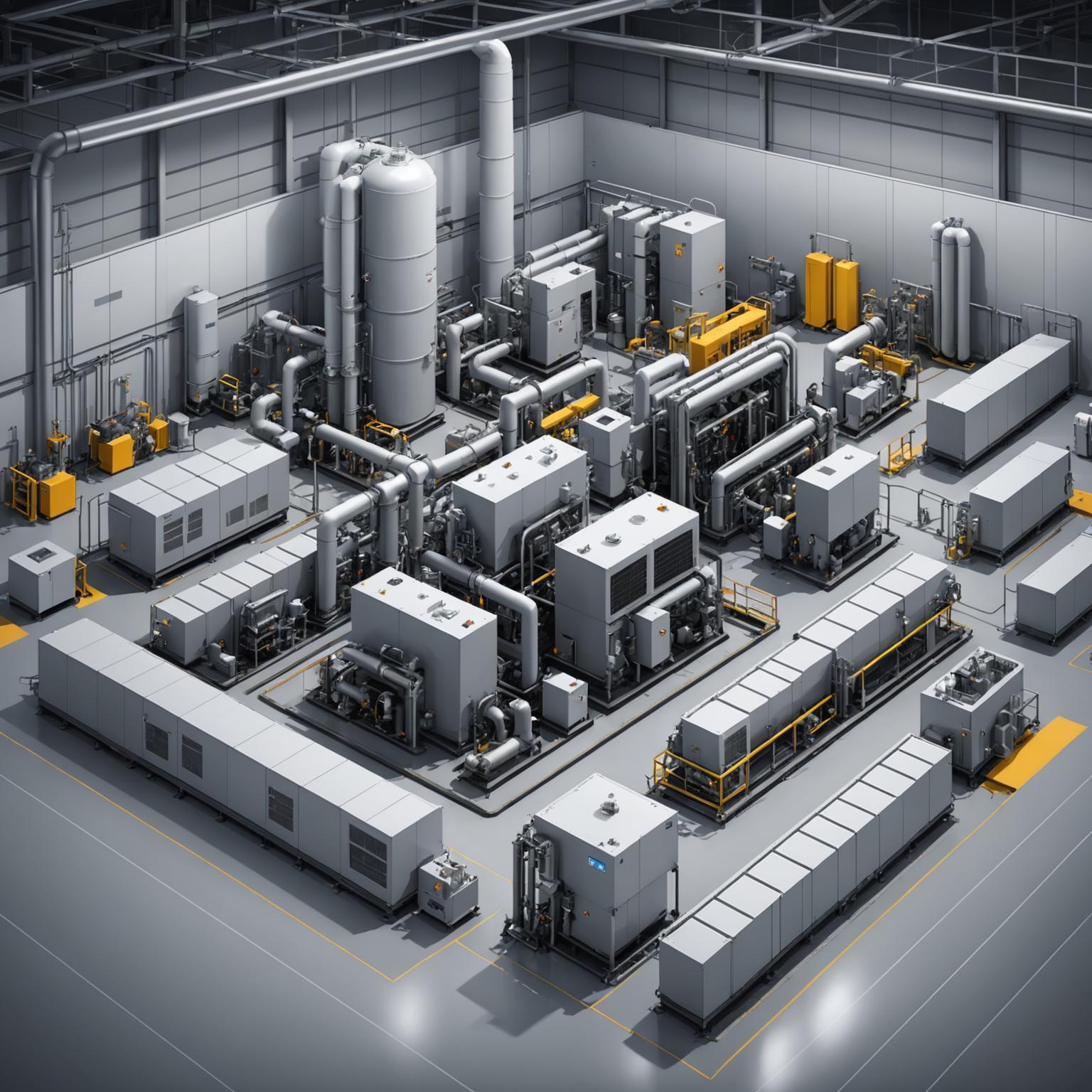

Understanding the Fundamentals of Industrial Cooling

At its core, an Industrial Chiller operates on a principle of heat transfer, utilizing a refrigeration cycle to cool a fluid, typically water or a water-glycol mixture. This cooled fluid is then circulated through process equipment to absorb heat, before returning to the chiller to be cooled again. This continuous loop is vital for maintaining thermal stability in applications where overheating could lead to product defects, equipment damage, or complete operational shutdowns. The system itself is comprised of four main components: an evaporator, a compressor, a condenser, and an expansion valve. The process liquid transfers its heat to a refrigerant in the evaporator, causing the refrigerant to turn into a gas. The compressor then pressurizes this gas, and the condenser releases the heat from the refrigerant into the ambient air or a water source. Finally, the expansion valve reduces the pressure of the refrigerant, cooling it down before it re-enters the evaporator to start the cycle anew. This elegant and efficient process is what makes the modern industrial chiller an indispensable tool across countless sectors.

Exploring Different Chiller Types: The Water Cooled Chiller

When exploring the market for a cooling solution, one of the primary distinctions you will encounter is between air-cooled and water-cooled chillers. While both are effective, the water cooled chiller offers distinct advantages, particularly for larger-scale or indoor applications. Unlike its air-cooled counterpart, which uses ambient air to dissipate heat from the condenser, a water cooled chiller transfers heat to a separate water source, which is then typically managed by a cooling tower. This method is generally more energy-efficient and provides more consistent performance, as water temperature is far more stable than air temperature. Furthermore, these units tend to operate much more quietly, a significant benefit for indoor installations where noise levels are a concern. Their compact footprint relative to their cooling capacity also makes them an ideal choice for facilities where space is at a premium. For demanding environments requiring high-capacity, stable cooling, this type of system is often the superior choice.

Essential Features to Consider for Your Next Purchase

When you begin browsing industrial chillers for sale, it is crucial to look beyond the basic cooling capacity and consider the features that contribute to usability, longevity, and overall return on investment. A modern unit should feature a user-friendly interface, such as an intuitive LCD control panel, that allows for precise temperature settings and real-time monitoring of system performance. This level of control empowers operators to optimize processes with ease. Durability is another non-negotiable factor. Look for units constructed with heavy-duty materials and a robust design capable of withstanding demanding industrial environments. Features like caster wheels for mobility can also be invaluable, offering flexibility in how and where the chiller is deployed. Integrated safety systems are equally important, providing warnings and protections against overloading or other operational faults, thereby safeguarding both the chiller and the equipment it services.

Versatile Applications: Where Industrial Chillers Shine

The application versatility of an Industrial Chiller is a testament to its importance. In the plastics industry, they are essential for cooling molds, which ensures faster cycle times and higher-quality parts. The manufacturing sector relies on them to cool everything from welding equipment and CNC machinery to hydraulic systems, preventing overheating and extending equipment life. In the world of high-tech electronics and laser cutting, the precision cooling provided by a chiller is critical for maintaining the tight tolerances required for these sensitive processes. Even the food and beverage industry depends heavily on chillers for processes like cooling ingredients, managing fermentation temperatures, and ensuring product safety and consistency. This broad utility underscores the chiller’s role as a foundational component of modern production.

The Dual Pillars of Performance: Efficiency and Durability

Investing in an industrial cooling system is a significant capital expenditure, which is why efficiency and durability are the twin pillars of a smart purchase. An energy-efficient unit can lead to substantial long-term savings on operational costs, reducing a facility’s overall power consumption without sacrificing cooling performance. This is not only beneficial for the company’s bottom line but also aligns with growing corporate responsibility and environmental consciousness. Durability is the other side of the coin. A well-built chiller, designed with high-quality components and thoughtful engineering, minimizes the risk of unexpected downtime and costly repairs. A reliable water cooled chiller, for instance, built to last in a demanding environment, ensures that your production lines keep moving, protecting your revenue stream and maintaining your reputation for dependability.

Making the Right Choice for Your Operations

In conclusion, selecting the right cooling system is a strategic decision that directly impacts operational efficiency, product quality, and profitability. Whether you require the high-efficiency performance of a water cooled chiller or another type of system, it is vital to assess your specific needs carefully. Consider the cooling load, the operating environment, and the key features that will provide the most value over the long term. By focusing on quality, durability, and user-friendly operation, businesses can find the perfect Industrial Chiller to serve as a reliable partner in productivity, ensuring that their critical processes remain cool, stable, and highly effective for years to come. The market for industrial chillers for sale is vast, but a well-informed choice will always yield the best results.