Titanium wire is a remarkable material praised for its exceptional combination of strength, lightness, and corrosion resistance. Its versatility makes it indispensable across a multitude of demanding fields, leading to a growing interest in its various forms and the ever-expanding scope of titanium wire applications. This article will delve into the unique characteristics of this metal, explore where it’s used, and offer guidance for those looking to source it from reputable channels.

Understanding the Unique Properties of Titanium Wire

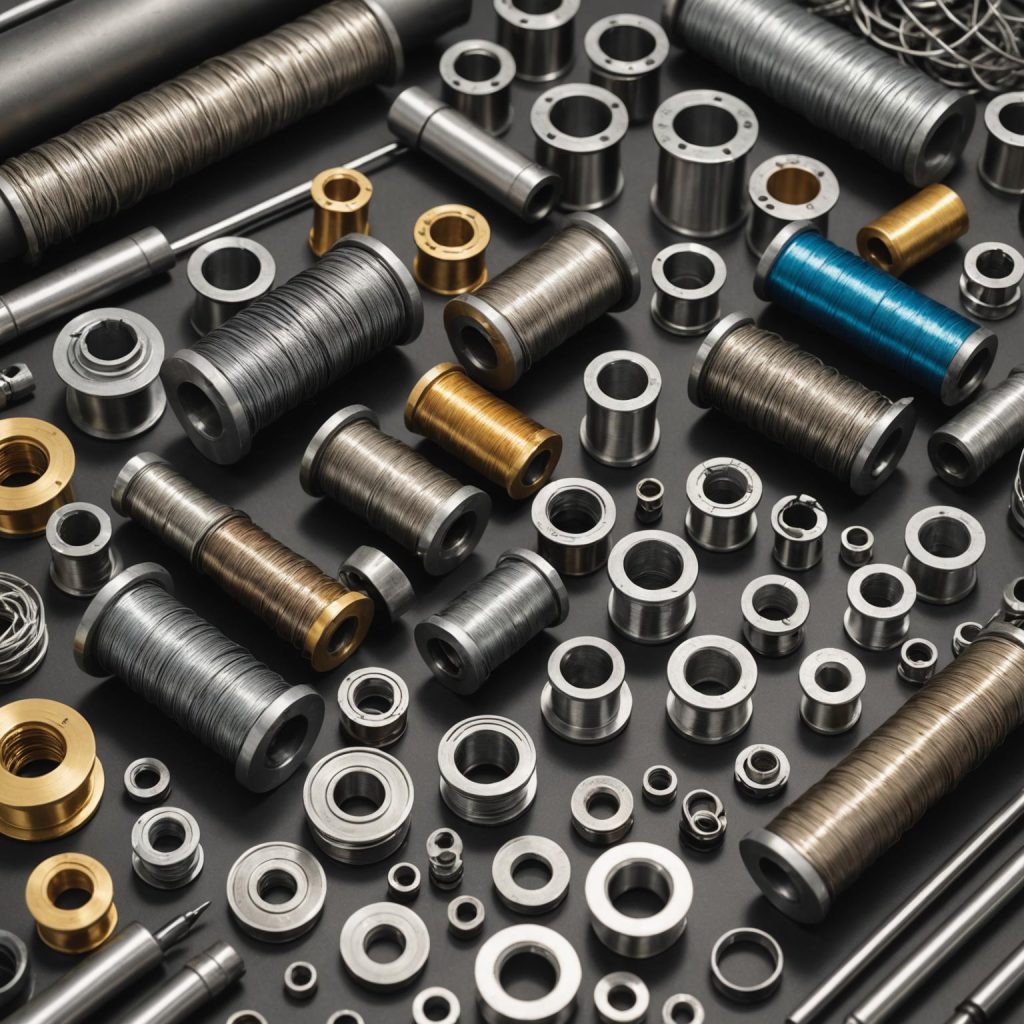

The allure of titanium wire stems largely from its extraordinary physical and chemical properties. Perhaps most notable is its superior strength-to-weight ratio, meaning it offers incredible toughness without the burden of excessive mass, a critical factor in industries like aerospace and performance sports. Furthermore, its exceptional resistance to corrosion, particularly against saltwater, chlorine, and many industrial chemicals, ensures longevity and reliability in harsh environments. Medical applications greatly benefit from this metal’s biocompatibility; the human body generally does not react adversely to it, making it ideal for implants. It also boasts a high melting point and good ductility, allowing it to be drawn into various wire gauges and shapes while maintaining integrity under thermal stress.

Diverse Titanium Wire Applications Across Industries

The practical uses of this advanced material are vast and varied, showcasing its adaptability. In the aerospace sector, it’s crucial for components in aircraft and spacecraft where weight reduction and high strength are paramount. The medical field heavily relies on titanium wire for surgical implants like pacemakers and orthopedic rods, as well as for dental implants and orthodontic wires, thanks to its biocompatibility and ability to fuse with bone. Its corrosion resistance makes it a prime candidate for marine applications, including shipbuilding components and equipment used in desalination plants. The chemical processing industry utilizes it for heat exchangers and piping systems exposed to corrosive substances. Beyond these, you will find forms of titanium in high-performance sports equipment, intricate jewelry designs, and as a filler material in welding processes, highlighting its broad utility.

Finding Reliable Titanium Wire Suppliers

When sourcing this specialized material, partnering with knowledgeable and reputable titanium wire suppliers is essential. A trustworthy supplier will typically offer a comprehensive range of titanium grades, such as commercially pure grades (1, 2, 3, 4) and alloys like Grade 5 (Ti-6Al-4V), each suited to different performance requirements. Look for suppliers who can provide material certifications confirming adherence to international standards (e.g., ASTM, ISO). Good titanium wire suppliers should also offer various wire diameters, forms (such as spools or straight lengths), and potentially custom solutions. Their expertise can be invaluable in guiding you to the correct product specification for your specific application, ensuring both quality and cost-effectiveness. Customer reviews, industry experience, and a commitment to quality control are also key indicators of a reliable partner.

Key Factors When You Buy Titanium Wire

Before you buy titanium wire, several factors should be carefully considered to ensure you select the optimal product. The specific grade of titanium is paramount, as different grades offer varying levels of strength, ductility, and corrosion resistance. For instance, Grade 2 is often used for its excellent formability and corrosion resistance, while Grade 5 is favored for its higher strength. The wire diameter and temper (annealed, hardened) will also significantly impact its suitability for your intended use. Consider the required quantity and whether you need it in spools or cut lengths. While price is always a factor, it should be weighed against the quality, consistency, and certifications offered. Investing in high-quality material when you buy titanium wire from a vetted source can prevent costly failures and ensure the longevity and performance of your end product.

The Expanding Future of Titanium Wire

The demand for titanium wire continues to grow as industries increasingly recognize its unique advantages. Ongoing research and development are focused on creating new titanium alloys with even more specialized properties, further broadening its potential applications. From advanced manufacturing techniques like 3D printing with this versatile wireform to its increasing use in renewable energy technologies and consumer electronics, the future looks bright. As innovation drives the need for materials that are stronger, lighter, and more durable, this particular wire product is well-positioned to meet these evolving challenges, solidifying its role as a critical material in modern engineering and design.