Understanding the Revolution of CNC Machines

CNC machines, or Computer Numerical Control machines, have reshaped the landscape of manufacturing, offering unprecedented precision and efficiency. Their integration into modern production lines marks a pivotal advancement in precision engineering. A CNC machine can automate complex processes, resulting in faster production with impeccable accuracy. As a result, industries ranging from automotive to aerospace rely heavily on CNC machining to produce high-quality components.

The CNC machine leverages advanced software to control intricate movements, enabling the creation of complex geometries and designs that were previously impossible or very costly to achieve manually. This capability not only boosts productivity but also ensures that each piece is a perfect match to its design specifications, reducing waste and errors. In particular, CNC lathe machines, a type of CNC machine, rotate the material against a single-point cutting tool, excelling in producing cylindrical parts.

The Significance of CNC Machining in Modern Manufacturing

CNC machining is a cornerstone of modern manufacturing technology. It enables the production of components with high precision and consistency, facilitating efficiencies that manual machining cannot match. The leap to using these machines means that industries can now produce parts at scale with exacting standards, minimizing human error and reducing time to market. A key related term here is CNC lathe, which highlights CNC’s versatility in producing varied component shapes.

Precision and speed are not the only benefits. CNC machines are also capable of handling a wide range of materials, including metals, plastics, and composites, providing flexibility for manufacturers. This adaptability, coupled with automation, translates into reduced labor costs and increased output quality. As a result, industries worldwide are increasingly adopting CNC technologies to stay competitive and meet the growing demands for high-quality goods.

The Pinnacle of Engineering: CNC-Machined Components

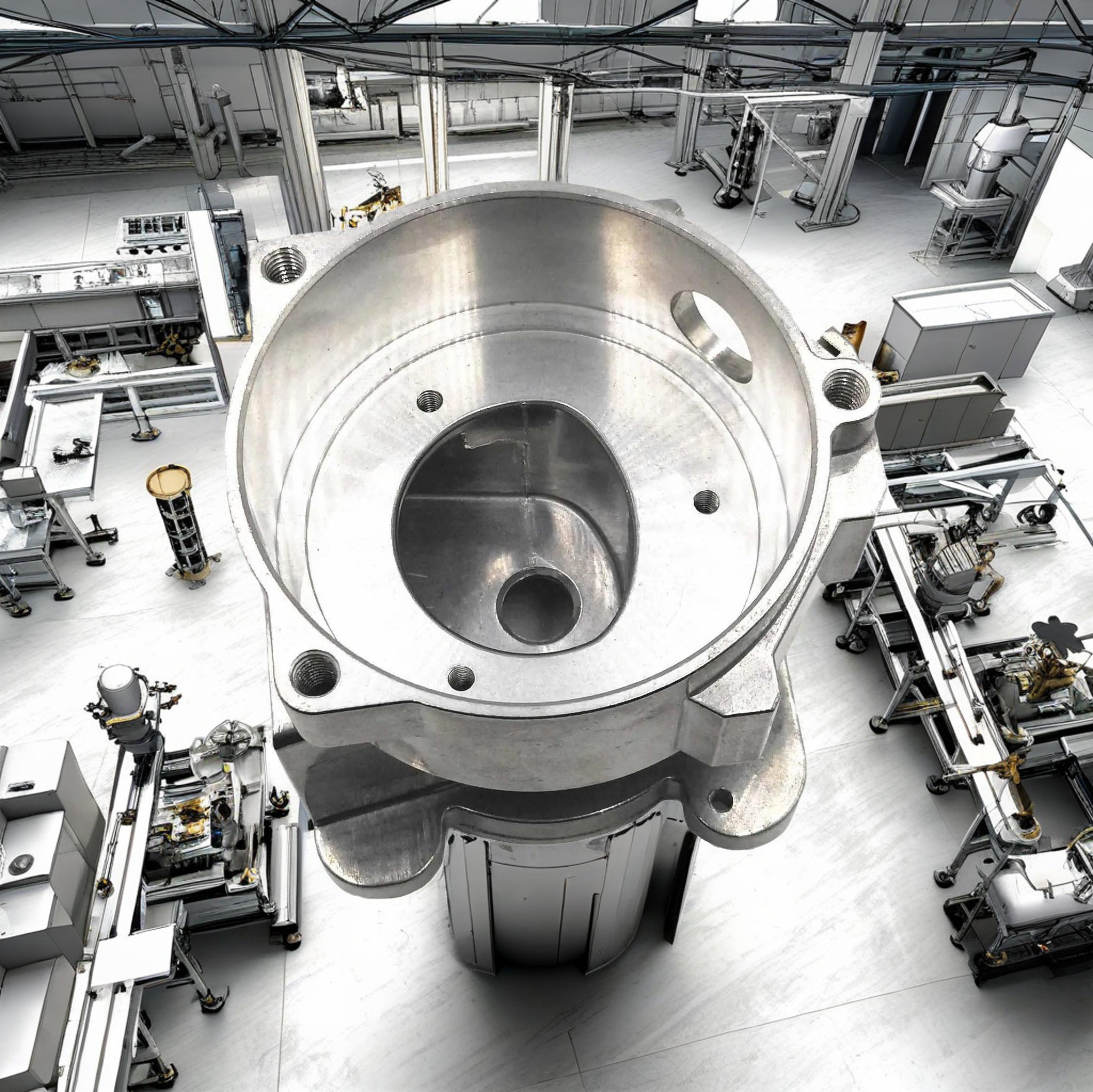

At the heart of modern industrial applications lies the CNC-machined aluminum component, a testament to the fusion of art and engineering. This component, characterized by its high-grade material and precise construction, epitomizes the potential unlocked by CNC technology. With its robust cylindrical design and precision-engineered fastening points, it sets new standards in performance and durability.

The metallic finish of CNC-machined components offers more than just aesthetics; it enhances resistance to corrosion and wear, making these parts suitable for even the most demanding environments. Industries require components that not only perform well but also last longer, and CNC machining delivers on both fronts. Its energy-efficient and lightweight design reduces system strain, potentially lowering maintenance costs and extending the lifespan of mechanical systems.

In conclusion, CNC machines are not simply tools for production; they are catalysts for innovation, efficiency, and precision in the industrial arena. By redefining what is possible in manufacturing, they continue to drive industries forward, ensuring that the components produced meet the highest standards of quality and performance. Their integration into manufacturing processes is not just a trend but a fundamental shift toward a more advanced and precise future.