As a designer, I remember a time when I felt creatively cornered. Every project seemed to be a battle between vision and reality, a struggle against the sheer weight and limitations of traditional building materials. I was sketching a concept for a new commercial lobby, envisioning vast, seamless surfaces and floating structures, but the practicality of using heavy stone or solid wood made it an engineering nightmare. It was during this frustrating search for a breakthrough that I first encountered the Aluminum honeycomb panel, a material that would not just solve a problem, but fundamentally change the way I approached design.

The Moment of Discovery

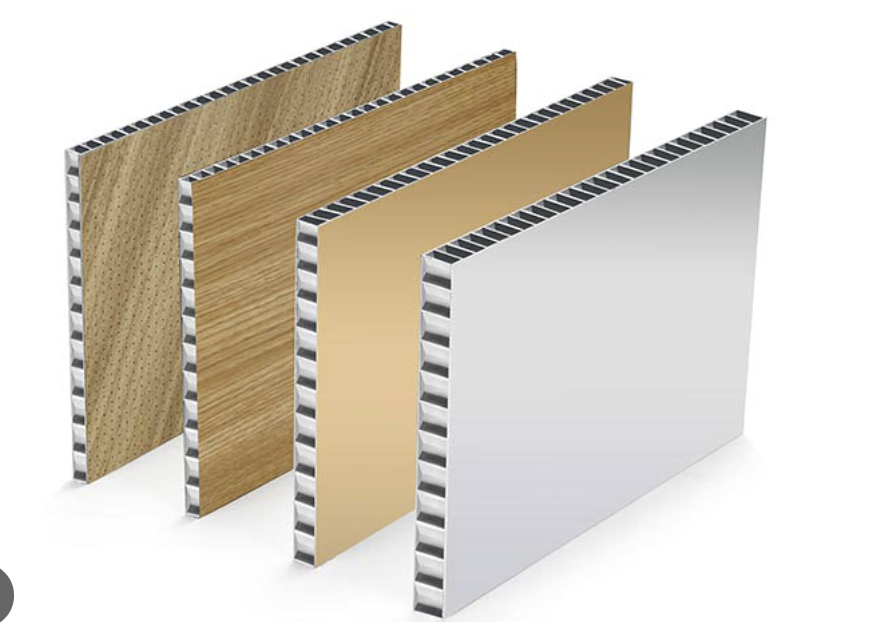

My initial skepticism was high. The samples that arrived were almost comically light. How could something that felt like it was filled with air possibly provide the structural integrity needed for architectural use? But then, I learned about its construction. The genius lies in its core, an intricate honeycomb structure of aluminum foil sandwiched between two aluminum sheets. This design, borrowed from the aerospace industry, creates an incredible strength-to-weight ratio. Holding one of these Lightweight aluminum panels was a revelation; it was rigid, perfectly flat, and impossibly strong for its mass. The barrier in my mind began to crumble. The limitations I had always accepted as given were suddenly no longer absolute.

From Blueprint to Breathtaking Reality

My first real test for the material was a bold one: the full exterior facade of a technology firm’s new headquarters. They wanted a look that was futuristic, sleek, and spoke of innovation. We chose panels with a metallic silver finish that gleamed in the sunlight, creating a dynamic, living surface that changed with the light of day. The installation was a dream. Large, expansive sheets were lifted and set into place with a fraction of the heavy machinery and time that conventional cladding would require. The result was a stunning, monolithic structure that seemed to defy gravity. This project opened my eyes to the sheer breadth of Honeycomb panel applications, proving they were not just for interiors but could redefine a building’s entire identity from the outside in.

Crafting Ambiance and Luxury Within

Soon after, a boutique hotel project landed on my desk. The client wanted an atmosphere of unique, eclectic luxury. This was my chance to explore the decorative potential of the panels. In the lobby, we used panels with a brushed gold finish to create a stunning feature wall behind the reception desk, instantly setting a tone of opulence. For the private suites, we utilized panels with a realistic wood grain texture for ceiling inserts and partitions. We achieved the warmth and natural beauty of wood without the weight, cost, or susceptibility to moisture. We could create elegant dividers and accent walls that felt substantial yet were simple to install, allowing for more complex and creative interior layouts. It was a testament to how these versatile panels could be tailored to create any desired mood or aesthetic.

Redefining Mobility and Efficiency

Perhaps the most telling project was for a client commissioning a custom luxury yacht. Here, every single gram of weight mattered. The challenge was to create an interior that felt as lavish and solid as a high-end apartment while adhering to strict weight limits for performance and fuel efficiency. The Lightweight aluminum panels were the undisputed hero of this build. We used them for everything: cabinetry, wall linings, partitions, and even furniture. The ability to have the look of solid marble or exotic wood with a fraction of the mass was transformative. This project perfectly illustrated one of the most critical Honeycomb panel applications: enabling high-end design in weight-sensitive environments like marine, aerospace, and specialty vehicles.

A Partner in Sustainable Design

Beyond the aesthetic and structural triumphs, my journey with the Aluminum honeycomb panel has been one of growing appreciation for its practical and ethical benefits. I’ve heard firsthand from construction crews how much they appreciate the ease of handling and reduced physical strain. I’ve spoken with clients years later who rave about the durability and the lack of maintenance required. But on a personal level, the sustainability of the material resonates deeply. In an industry often criticized for its environmental impact, using a material that is 100% recyclable allows me to create with a clearer conscience. It adds another layer of value to the design, one that speaks to longevity and responsibility. This material isn’t just a choice for a single project; it has become a cornerstone of my commitment to smarter, more sustainable building practices. It represents a future where innovative design and environmental stewardship go hand in hand.