Elena, an architect with two decades of experience, often found herself sketching impossible structures late at night. Her designs pushed the boundaries of form and function, but they frequently collided with the unyielding laws of physics and the limitations of traditional materials. She dreamed of facades that could soar without immense structural support, interiors that could be reconfigured with ease, and materials that were both visually stunning and environmentally responsible. For years, this dream remained confined to her notebooks, a silent testament to the gap between imagination and reality. That was until she first encountered the Aluminum honeycomb panel, a material that felt less like an incremental improvement and more like a quantum leap in building technology.

The initial sample she held in her hands was baffling. It was impossibly light, yet when she tried to bend it, it exhibited a rigidity that defied its weight. Her engineering curiosity took over as she learned about its composition. Inspired by the genius of nature’s own design—the bee’s honeycomb—the core of the panel was a lattice of hexagonal aluminum cells. This structure was the secret, creating a series of interconnected I-beams that distributed force across the entire surface. This elegant solution provided immense compressive and shear strength while using a fraction of the material required for a solid panel. It was the epitome of Lightweight aluminum panels, solving the age-old conundrum of strength versus weight that had constrained so many of her past projects. The material didn’t just feel new; it felt like the future she had been sketching all along.

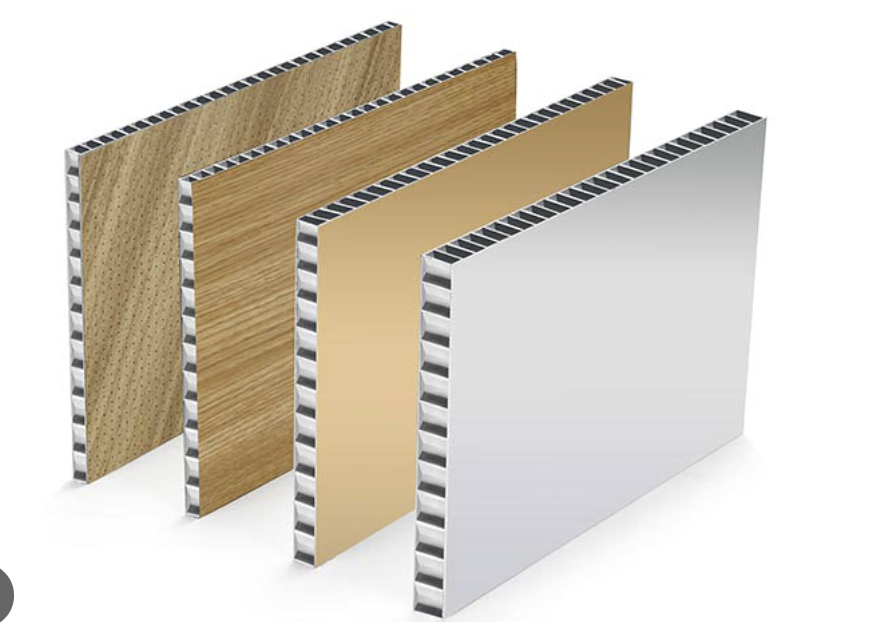

Suddenly, the possibilities seemed endless. The scope of Honeycomb panel applications began to fill her mind, transforming her theoretical designs into tangible plans. For a high-rise tower project in a bustling downtown, she envisioned a sleek, modern silver facade that would shimmer in the sunlight, its lightweight nature reducing the load on the building’s foundation and drastically cutting down on the required structural steel. For a suburban community center, she pictured interior walls clad in a warm, natural wood grain finish, creating a welcoming and organic atmosphere. These panels weren’t just for walls; she saw them as suspended ceilings, furniture components, and even artistic installations. The beige tones and other custom finishes meant she no longer had to compromise her aesthetic vision for performance. The versatility was astounding, allowing the same core technology to be applied to a modern minimalist residence or a grand commercial entryway with equal success.

As Elena specified the panels for her next project, a coastal arts museum, she delved deeper into their long-term performance. The coastal environment was harsh and unforgiving, a constant barrage of salt spray, humidity, and intense sun. Traditional materials would corrode, fade, or warp within years. However, these panels were engineered for endurance. Their surfaces were treated to be highly resistant to environmental pollutants, UV degradation, and corrosion, ensuring the museum’s facade would look as pristine in a decade as it did on opening day. Furthermore, the inherent fire-resistant characteristics of aluminum provided a level of safety that was non-negotiable for a public institution. This wasn’t just a choice for beauty; it was a choice for longevity, safety, and peace of mind for herself and her client.

The narrative of these innovative panels extended beyond just the design and durability. During the construction phase of the arts museum, Elena received an unexpected call from the site foreman. He was amazed. His crew was able to install the large facade sections with a smaller team and less heavy equipment than they had budgeted for. The Lightweight aluminum panels were not only a design advantage but a significant logistical and financial one. The ease of handling accelerated the construction timeline, saving the project valuable time and money. This practical benefit was a powerful story in itself, demonstrating how thoughtful material science could ripple through the entire lifecycle of a building, from the architect’s first sketch to the final construction invoice. The material’s efficiency wasn’t just in its structure, but also in its real-world application.

Now, when Elena walks past the finished museum, she sees more than just a building. She sees a story of innovation. She sees the honeycomb-inspired core working silently, providing strength and stability. She sees the durable finish withstanding the coastal air, a testament to modern engineering. The diverse Honeycomb panel applications she once only dreamed of are now a physical reality, shaping the experiences of everyone who interacts with the space. Her journey with the Aluminum honeycomb panel had transformed her practice, empowering her to bridge the gap between her boldest visions and the built environment. It proved to her that with the right materials, the impossible structures she once sketched late at night could finally stand tall in the light of day, reshaping our world one beautiful, efficient, and lightweight panel at a time.

评价

Clear filters目前还没有评价