A Designer’s Vision, A Material’s Promise

As an architectural designer, I’ve always been driven by the desire to create spaces that are not only functional but also emotionally resonant and visually breathtaking. For years, I carried a vision for a multi-use community arts center, a building that would feel both monumental and light, blending industrial strength with natural warmth. The concept involved vast, open interiors and a dramatic cantilevered roof that seemed to float above the entrance. The problem, however, was always the materials. Traditional options were too heavy, too costly, or simply couldn’t deliver the aesthetic I envisioned. My dream project remained locked in my sketchbook until a colleague introduced me to a game-changing material: the Aluminum honeycomb panel. It was a term I’d heard, but one I hadn’t explored. That introduction would change everything.

The Challenge of Weight and Vision

My primary obstacle was structural physics. The cantilevered roof needed to extend twenty feet without visible supports, creating a seamless transition from the outdoors to the grand atrium within. Concrete or steel would require massive, unsightly counterweights and support columns, completely undermining the feeling of weightlessness I wanted to achieve. Furthermore, the interior design called for large, unbroken wall surfaces that could be finished to look like natural wood in the library and a sleek metal in the galleries. Hauling and installing solid wood or metal panels of that size would be a logistical and financial nightmare. I needed a material that was strong yet ethereal, versatile yet durable. I was looking for a miracle, and I was about to find one in the most unexpected form.

The Breakthrough with Lightweight Panels

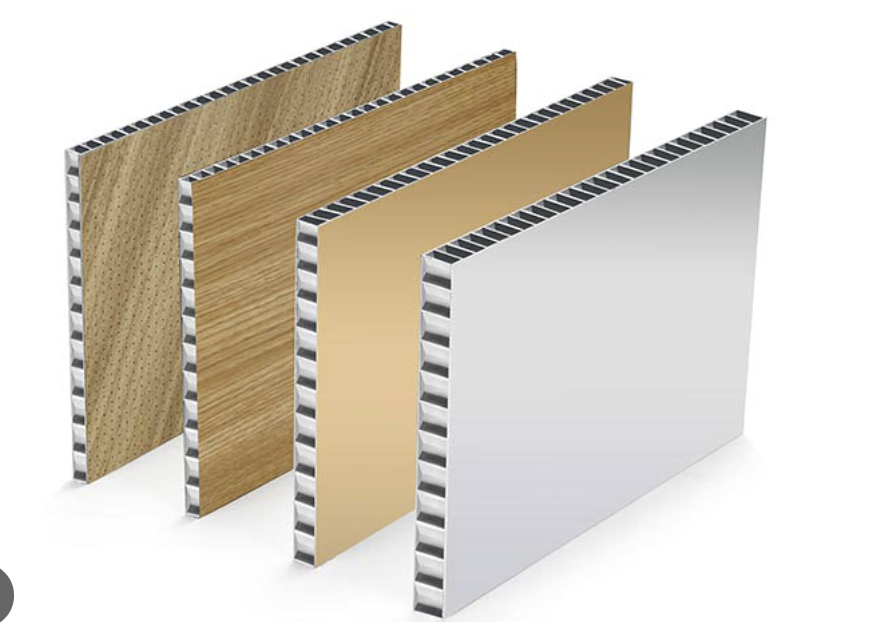

My research into the Aluminum honeycomb panel led me to a stunning innovation: a sandwich panel with an aluminum honeycomb core. The genius was in its structure, inspired by the natural efficiency of a beehive. A core of hexagonal aluminum cells was bonded between two thin but incredibly strong outer skins. This design created one of the most remarkable strength-to-weight ratios available in modern construction. These were truly lightweight aluminum panels, a fraction of the weight of solid aluminum or other traditional cladding materials, yet they offered immense rigidity and flatness over large surfaces. This was the solution to my cantilever problem. We could engineer the dramatic roofline without compromising the open, airy feel of the entrance. The reduced structural load meant a smaller foundation, less steel framing, and significant cost savings across the board.

Exploring a World of Honeycomb Panel Applications

The more I learned, the more I realized the potential of this material went far beyond just the roof. The sheer variety of finishes available opened up a world of honeycomb panel applications for both the exterior and interior of the arts center. My initial concern that a lightweight material might feel cheap or temporary was quickly dispelled. I was presented with a catalog of premium veneers bonded directly to the panels. For the quiet, contemplative library space, I chose a finish that perfectly mimicked the warm, rich grain of dark walnut. For the bustling atrium, a chic metallic gold finish would be used for accent walls, catching the light and adding a touch of luxury. The exterior cladding would utilize a sleek, brushed aluminum finish that would give the building a modern, sophisticated facade that shimmered in the changing daylight. Suddenly, I wasn’t just solving a structural problem; I was working with a design palette that offered limitless creative freedom.

From Blueprint to Reality

The construction phase was a revelation. The crew, accustomed to wrestling with heavy materials and coordinating cranes for every large installation, was astounded. The lightweight aluminum panels were easy to transport, handle, and mount. A two-person team could effortlessly install massive wall sections that would have previously required a full crew and heavy machinery. This efficiency dramatically accelerated our construction timeline and reduced labor costs. The precision-engineered panels fit together flawlessly, creating the seamless, monolithic surfaces I had envisioned in my earliest sketches. We used the material everywhere—as partition walls, ceiling tiles, and even for custom furniture. The versatility of these honeycomb panel applications proved to be one of the project’s greatest assets, allowing us to maintain a consistent design language throughout the entire building.

Functionality That Endures

As the arts center neared completion, the hidden benefits of the Aluminum honeycomb panel became apparent. Beyond its visual appeal, the panel’s core structure provided excellent thermal and acoustic insulation. The atrium, despite its soaring ceilings and glass facade, remained comfortably temperate, reducing the load on the HVAC system. Inside the library and workshop spaces, the panels helped to dampen sound, creating a peaceful and productive atmosphere free from the echoes and reverberations common in large, open-plan buildings. The material’s inherent resistance to corrosion, moisture, and fire gave us peace of mind that this beautiful building was also safe, durable, and sustainable. It was engineered not just for opening day, but for decades of community enjoyment. The choice of these advanced panels ensured the building was as high-performing as it was visually stunning, representing a truly holistic approach to design.