It all started with a project that felt nearly impossible. I was working with a client who envisioned a sprawling, cantilevered canopy for a luxury boutique hotel’s rooftop lounge. They wanted something that felt ethereal and modern, almost floating, yet it had to withstand coastal winds and weather with unwavering strength. My team and I ran through the usual suspects: solid steel was too heavy and would require a prohibitively massive support structure; wood couldn’t provide the sleek, futuristic finish they desired; other composites were either too expensive or lacked the long-term durability for an exterior application. We were at a standstill, staring at a beautiful design on paper that seemed destined to remain a fantasy. That’s when a colleague, fresh from an international materials expo, slid a sample across my desk. It was an Aluminum honeycomb panel, and it would change everything.

A Designer’s Dilemma: The Search for the Perfect Material

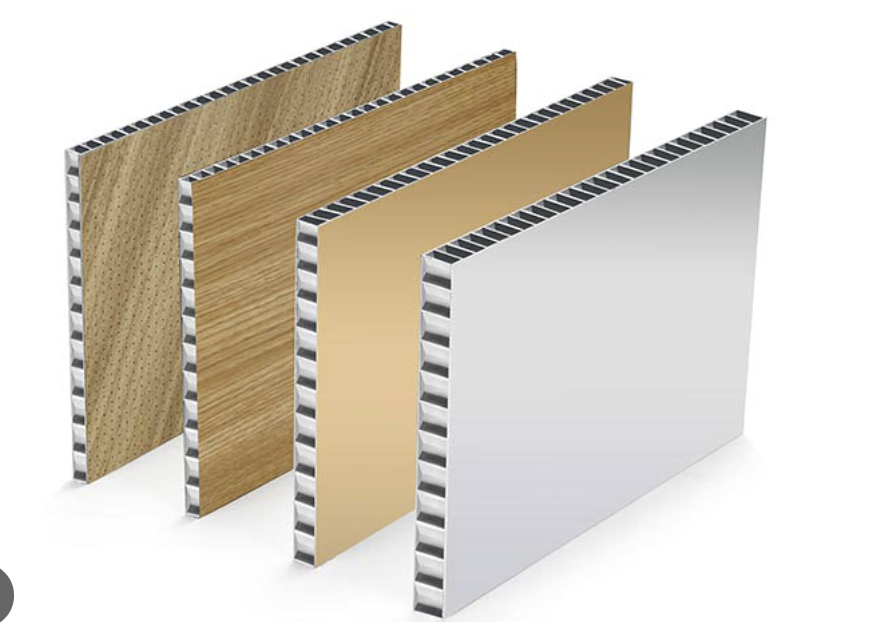

At first glance, the sample didn’t look like much. It was a thin slice, maybe an inch thick, with a metallic skin. But when I picked it up, I was genuinely shocked. It felt practically weightless, yet when I tried to bend or twist it, it resisted with the stubbornness of a solid metal plate. My colleague explained the genius of its design, a concept borrowed directly from nature. Inside, sandwiched between two thin but robust aluminum sheets, was an intricate honeycomb lattice. This core, a matrix of hexagonal cells, was the secret. It created an incredible structural rigidity while being composed mostly of empty space. This was the breakthrough we needed, a new category of Lightweight aluminum panels that offered the strength of traditional materials without the burdensome mass. We immediately requested larger samples, and the possibilities began to unfold. They came in the exact finishes we needed—a sleek, brushed metallic sheen that perfectly captured the contemporary chic our client was after, and even a stunningly realistic wood grain texture that we bookmarked for future interior projects.

The Revelation: From Blueprint to Breathtaking Reality

The moment we started incorporating the panels into our revised blueprints, the entire project became viable. The reduced weight meant we could achieve the long, dramatic overhang the client dreamed of without turning the rooftop into a forest of thick support columns. The installation phase was a narrative of efficiency. A small crew could easily handle the large panels, significantly cutting down on labor time and costs. What would have taken weeks with conventional materials was assembled in days. This is where the true beauty of these panels shines, in the seamless fusion of form and function. Exploring the range of Honeycomb panel applications for this project alone was eye-opening. While the canopy was the main event, we also utilized them to create floating interior partition walls in the lounge, providing a sense of separation without visually closing off the space. Their inherent acoustic-dampening properties were an unexpected but welcome bonus, helping to create a more intimate and serene atmosphere amidst the city bustle.

Beyond the Build: A New World of Possibilities

That hotel project was a turning point in my career, not just for its success, but for how it expanded my material vocabulary. It made me look at design challenges through a new lens. I started seeing the vast potential of this technology everywhere. My curiosity led me to research other Honeycomb panel applications, and I was fascinated to learn how widely they were already being used in the world’s most demanding industries. In aerospace, they form floors, galleys, and bulkheads in aircraft where every ounce matters. In the marine industry, they are used to build lightweight and durable yacht interiors and superstructures that are resistant to the corrosive sea environment. High-speed trains use them for their paneling to reduce weight and increase speed and efficiency. The panels were not just for architecture; they were a core component of modern engineering, a testament to the power of a simple, brilliant design. The sheer versatility is astounding, opening up a world of creative possibilities for any designer willing to think outside the box.

A Sustainable Choice for a Modern World

My appreciation for the Aluminum honeycomb panel deepened further when I considered its environmental credentials. In an era where sustainable design is no longer a preference but a professional responsibility, these panels stand out. Their innovative construction means a drastic reduction in the amount of raw material needed compared to a solid panel of equivalent strength. This efficiency in manufacturing is a significant win for conservation. Furthermore, their core structure provides enhanced thermal insulation properties. For our rooftop project, this meant the area under the canopy remained noticeably cooler on hot days, a passive energy-saving feature that added tangible value for the client and their guests. Choosing these panels was not just a smart engineering decision; it was a conscious step toward more responsible, eco-friendly construction, proving that cutting-edge technology and sustainability can go hand in hand.

A Legacy of Innovation

Years later, that rooftop canopy still stands as a landmark, as sleek and stunning as the day it was completed. It serves as a constant reminder of how a single material can unlock a design and inspire a new way of thinking. The journey from a seemingly impossible sketch to a celebrated reality was paved by the discovery of these remarkable Lightweight aluminum panels. They embody the perfect blend of aesthetic sophistication, unparalleled structural integrity, and forward-thinking sustainability. They taught me that sometimes, the most elegant solutions are hidden in plain sight, or in this case, within the beautiful and efficient geometry of a honeycomb. For any architect, designer, or builder, they are not just a material, but an invitation to push boundaries and build the future.