In the intricate and demanding world of modern industry, countless pieces of sophisticated equipment work in unison to drive automation, manufacturing, and innovation. Behind every robotic arm, digital display, and complex control system lies an unsung hero: the power source. A high-quality Industrial switching power supply is the lifeblood of these systems, providing the stable, efficient, and reliable energy necessary for them to function flawlessly. More than just a component, it is a foundational element that ensures operational continuity, protects sensitive electronics from damage, and ultimately dictates the performance and longevity of the entire industrial ecosystem. Choosing the right power supply is not merely a technical decision; it’s a strategic investment in reliability and productivity.

Unpacking the Core Technology: The Switching Power Supply

At its heart, the technology that makes this reliability possible is the switching power supply. Unlike its older, bulkier predecessors, the linear power supply, this modern design utilizes high-frequency switching regulators to convert electrical power with remarkable efficiency. The process involves rapidly switching a series of electronic components, such as transistors, on and off thousands of times per second. This high-frequency operation allows for the use of much smaller transformers, inductors, and capacitors, resulting in a unit that is significantly more compact, lightweight, and efficient. While linear supplies would dissipate excess energy as heat, a switching design minimizes this waste, often achieving efficiency ratings well above 80 or 90 percent. This not only reduces energy consumption and operational costs but also lowers the thermal stress on surrounding components, contributing to a longer service life for the entire assembly.

The Conversion Process: Understanding the AC to DC Power Supply

Most industrial machinery and electronic devices do not run on the alternating current (AC) that comes from a standard wall outlet. They require a steady, direct current (DC) to power their sensitive microprocessors, sensors, and motors. This is the primary function of an AC to DC power supply. The conversion journey begins when AC voltage enters the unit. First, it is rectified, a process that converts the oscillating AC waveform into a pulsating DC signal. This raw DC is then smoothed out by large capacitors to reduce ripples. Finally, the switching regulator, as mentioned earlier, precisely controls the output to deliver a constant and stable DC voltage, regardless of fluctuations in the input line voltage or changes in the load demand. This stable output is absolutely critical; an inconsistent power source can lead to system errors, data corruption, premature component failure, and costly downtime, making a high-quality AC to DC power supply indispensable for any serious industrial application.

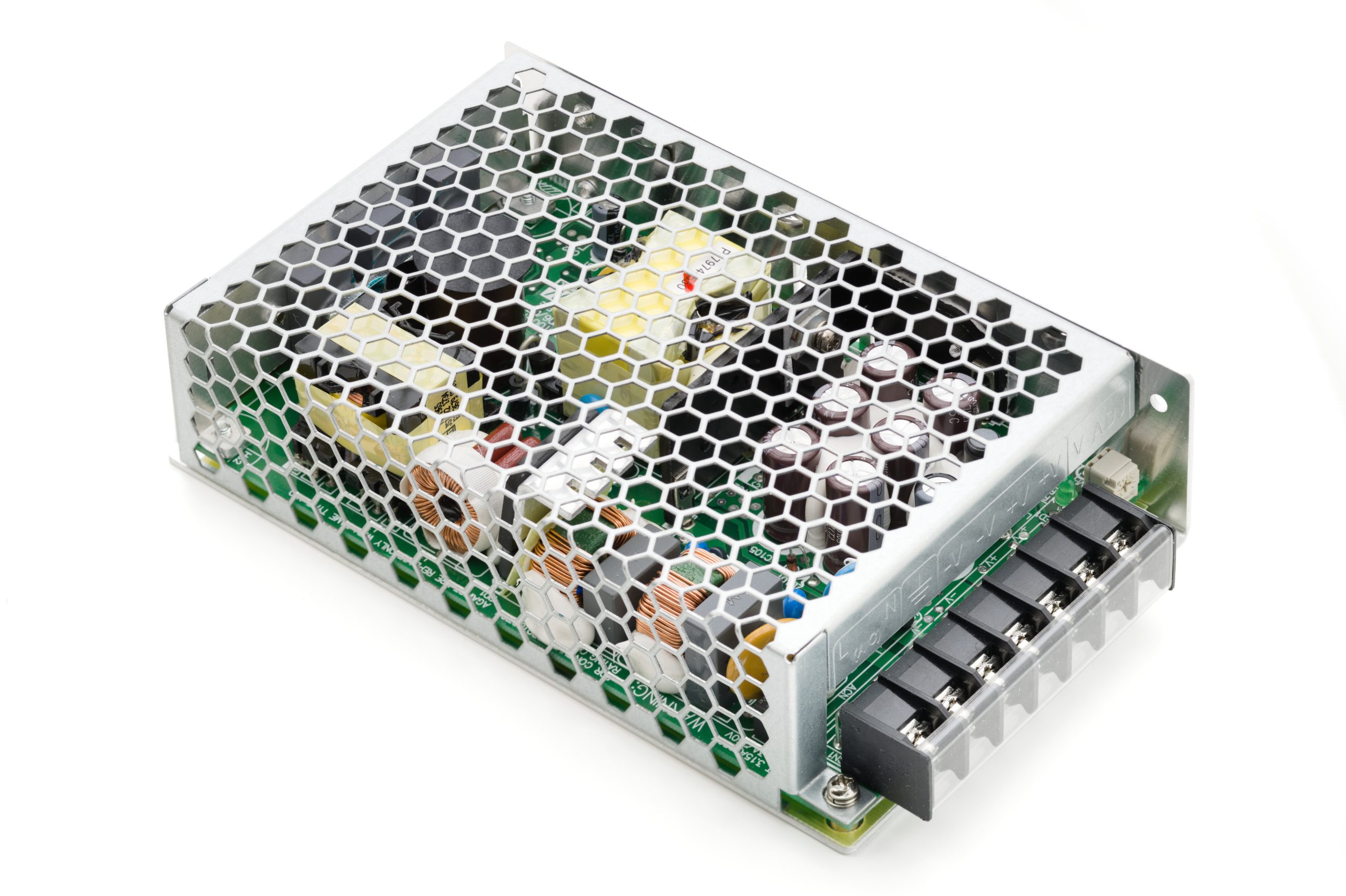

Engineered for Endurance: The Anatomy of a Modern Industrial Power Supply

A truly robust industrial power supply is a marvel of thoughtful engineering, designed to withstand the rigors of its environment. A prime example of this is a unit enclosed in a high-strength perforated alloy shell, often featuring a hexagonal honeycomb design. This pattern is not just for aesthetics; it is a highly functional feature that maximizes ventilation and promotes passive heat dissipation. The open-frame structure further enhances airflow, ensuring that internal components remain at safe operating temperatures even under heavy, continuous use. Peering inside, the meticulous craftsmanship becomes evident. High-grade capacitors and robust inductors are carefully selected and laid out to deliver a stable, efficient power output. These components are the backbone of the unit’s performance, providing the clean energy needed for demanding automation equipment and advanced electronics. Connectivity is also streamlined through a secure and intuitive terminal block, ensuring tight, reliable connections that simplify system integration and reduce the risk of wiring faults.

Safety and Reliability: The Non-Negotiable Features

Beyond performance, safety and reliability are paramount in industrial settings where electrical failures can have severe consequences. A top-tier Industrial switching power supply integrates a suite of protective features to safeguard both the unit itself and the equipment it powers. Essential protections include over-current protection, which prevents damage from excessive electrical draw; over-voltage protection, which shields connected devices from damaging voltage spikes; and short-circuit protection, which instantly shuts down the output in the event of a wiring fault to prevent fire or equipment destruction. Furthermore, compliance with stringent international safety standards, such as UL and CE, serves as a testament to its quality. This certification signifies that the power supply has undergone rigorous testing for safety, performance, and electromagnetic compatibility, giving users confidence that they are deploying a device that is not only powerful but also exceptionally reliable and safe for any commercial or industrial environment.

Inspiring Innovation Across Industries

The versatility and dependability of these power units have made them integral to a vast array of sectors. In factory automation, they power the PLCs, motors, and sensors that orchestrate complex assembly lines. In the world of digital signage and large-scale LED displays, they provide the consistent energy needed for vibrant, flicker-free visuals. Telecommunication hubs rely on them for uninterrupted service, while advanced medical equipment uses them to ensure life-saving devices function without fail. By providing a foundation of stable and efficient energy, the modern industrial power supply does more than just power a machine; it empowers innovation, supports critical infrastructure, and drives progress across countless fields, proving that sometimes the most important components are the ones working silently in the background.