The Unseen Sentinels: Exploring Essential Transformer Accessories

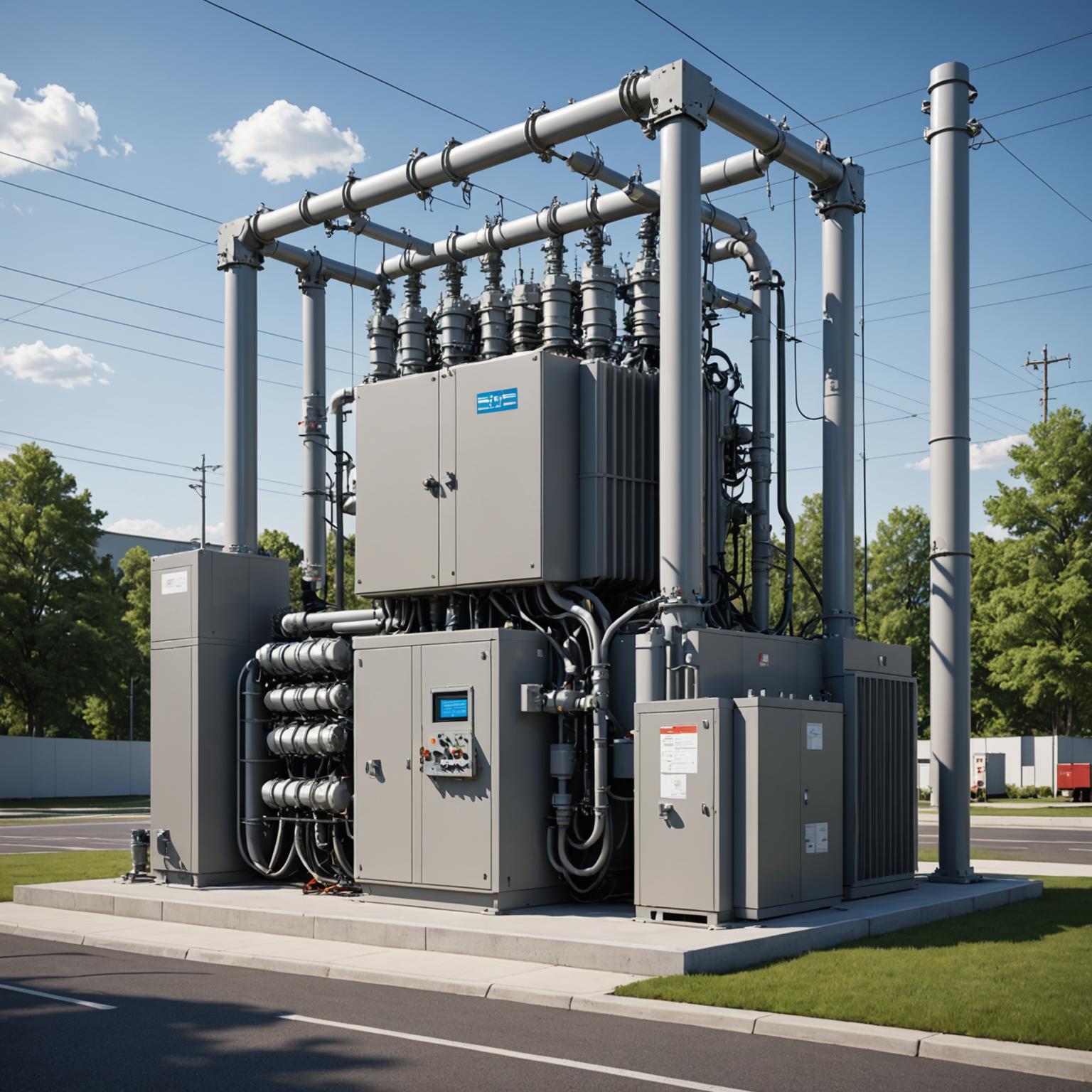

Transformers, the silent workhorses of our electrical grids, play an indispensable role in ensuring that power is delivered reliably and efficiently from generation sources to consumers. While the core and windings form the heart of a transformer, a sophisticated array of components, collectively known as transformer accessories, are crucial for its optimal performance, safety, and longevity. Understanding the function and importance of each transformer accessor is paramount for anyone involved in power system design, operation, or maintenance. These components are not mere additions; they are integral parts that monitor, protect, and facilitate the smooth operation of these critical assets, forming the first line of defense in proactive transformer maintenance strategies.

Guarding and Guiding: Monitoring and Control Accessories

A significant category of transformer accessories is dedicated to monitoring the various operational parameters that indicate a transformer’s health. Precision-engineered gauges and sensors constantly track critical data points. For instance, temperature monitors, such as Winding Temperature Indicators (WTIs) and Oil Temperature Indicators (OTIs), provide real-time thermal readings. Excessive heat is a primary enemy of transformers, accelerating insulation degradation. These indicators alert operators to abnormal temperature rises, allowing for timely intervention before catastrophic failure occurs. Similarly, pressure monitoring devices, like pressure relief valves and Buchholz relays, are vital. The Buchholz relay, a gas and oil actuated device, is particularly ingenious, capable of detecting incipient faults such as slow gas accumulation from minor discharges or rapid pressure surges from more severe internal short circuits. Control units, often housed in marshalling boxes, centralize the connections from these monitoring devices, providing a coherent interface for operational adjustments and alarm signaling. This intricate network of monitoring systems forms a cornerstone of effective transformer maintenance, offering a window into the transformer’s internal state without requiring disruptive internal inspections.

The Lifeblood and Its Keepers: Transformer Oil Management Accessories

For oil-immersed transformers, the transformer oil serves as both a coolant and an dielectric insulator. Maintaining the quality and quantity of this oil is critical, and several transformer accessories are dedicated to this task. Oil level indicators, such as Magnetic Oil Level Gauges (MOGs), provide a clear visual representation of the oil volume within the main tank and conservator. Low oil levels can lead to insufficient cooling and compromised insulation, potentially causing overheating or electrical breakdown. Conversely, excessively high levels could indicate abnormal conditions. Special valves, like drain valves and sampling valves, are essential for managing the transformer oil. Drain valves allow for the removal of oil for replacement or processing, while sampling valves enable technicians to draw small quantities of oil for diagnostic testing. Analysis of transformer oil can reveal a wealth of information about the transformer’s internal condition, identifying dissolved gases indicative of faults, moisture content, or oil degradation. Thus, accessories facilitating oil management are directly linked to the health and longevity of the transformer, playing a key role in preventing premature aging and failure.

Ensuring Dielectric Integrity: Bushings and Insulators

Bringing high voltage connections into and out of the grounded transformer tank requires specialized transformer accessories known as bushings. These components provide a sealed, insulated pathway for conductors, preventing electrical flashovers between the live parts and the earthed tank. Bushings can be made from various materials, including porcelain or advanced polymer composites, often oil-filled or resin-impregnated paper (RIP) types for higher voltages. Their design must withstand significant electrical, thermal, and mechanical stresses. The integrity of these bushings is paramount; a failed bushing can lead to a catastrophic transformer failure, often accompanied by fire. Regular inspection of bushings for cracks, contamination, or oil leaks is a critical aspect of transformer maintenance. The glossy, often brown or grey, finish on many porcelain insulators is not just aesthetic; it provides a smooth surface that resists the accumulation of dirt and moisture, which could otherwise create conductive paths and lead to tracking or flashover, especially in polluted environments. These robust components are game-changers in maintaining the high-voltage insulation systems vital for power transmission and distribution.

Protective Mechanisms: Safeguarding Against Overpressure and Faults

Beyond routine monitoring, certain transformer accessories are designed for active protection. Pressure Relief Devices (PRDs) are crucial safety components that vent excessive internal pressure which might build up due to severe internal faults. Without a PRD, the transformer tank could rupture, leading to oil spills, fires, and extensive damage. These devices are engineered to operate rapidly when a predetermined pressure threshold is exceeded, safely releasing the pressure and mitigating the consequences of a fault. Furthermore, tap changers, which allow for a_djustment of the transformer’s voltage ratio, come with their own suite of protective accessories and intricate control mechanisms. Whether on-load (OLTC) or de-ener_gized (DETC), these components are themselves complex pieces of machinery integrated into the transformer system. Properly functioning tap changers ensure stable voltage supply under varying load conditions, and their accessories contribute to their reliable operation.

Facilitating Flow and Cooling: Valves and Radiators

Efficient cooling is essential for a transformer’s operational life, and accessories related to the cooling system are therefore vital. Radiators, through which transformer oil circulates to dissipate heat, are a prominent feature. Valves are strategically placed to isolate sections of the cooling system, such as individual radiators, for maintenance or replacement without draining the entire transformer. These could include robust butterfly valves or gate valves, designed for longevity and reliable sealing in industrial environments. For forced cooling systems, fans and oil pumps are additional accessories that require their own monitoring and control to ensure they operate effectively when needed. The correct functioning of these cooling system components directly impacts the transformer’s ability to handle its rated load and manage thermal stresses, contributing significantly to overall reliability. Efficient fluid control management, ensured by high-quality valves, allows for precise flow rates and airtight seals, critical for both cooling efficiency and preventing leaks of transformer oil.

The Sum of Its Parts: The Holistic Importance of Accessories

Ultimately, a transformer is more than just its core and windings; it is a complex system where every transformer accessor plays a defined and important role. From the smallest oil sampling valve to the sophisticated Buchholz relay, each component contributes to the transformer’s overall safety, reliability, and operational efficiency. Investing in high-quality, well-maintained accessories translates directly into enhanced asset life, reduced unplanned outages, and safer working environments. Regular inspection, testing, and timely refurbishment or replacement of these accessories are fundamental aspects of a comprehensive transformer maintenance program. Neglecting these seemingly minor components can lead to major failures, significant financial losses, and disruptions to power supply. Therefore, a deep appreciation and thorough understanding of transformer accessories are indispensable for ensuring the enduring performance of our critical power infrastructure, safeguarding the flow of energy that powers our world.