The Growing Demand for High-Performance Materials

The modern world increasingly relies on materials that offer exceptional performance under demanding conditions. Among these, titanium stands out for its unique combination of strength, lightness, and corrosion resistance. As industries seek innovation and efficiency, the demand for components made from this remarkable metal, such as fine titanium wire, is on the rise. Consequently, identifying reliable titanium wire suppliers is becoming a critical step for manufacturers looking to integrate high-quality materials into their products. This material’s journey from raw ore to precision-engineered filament involves sophisticated processes, resulting in a product vital for numerous advanced technologies.

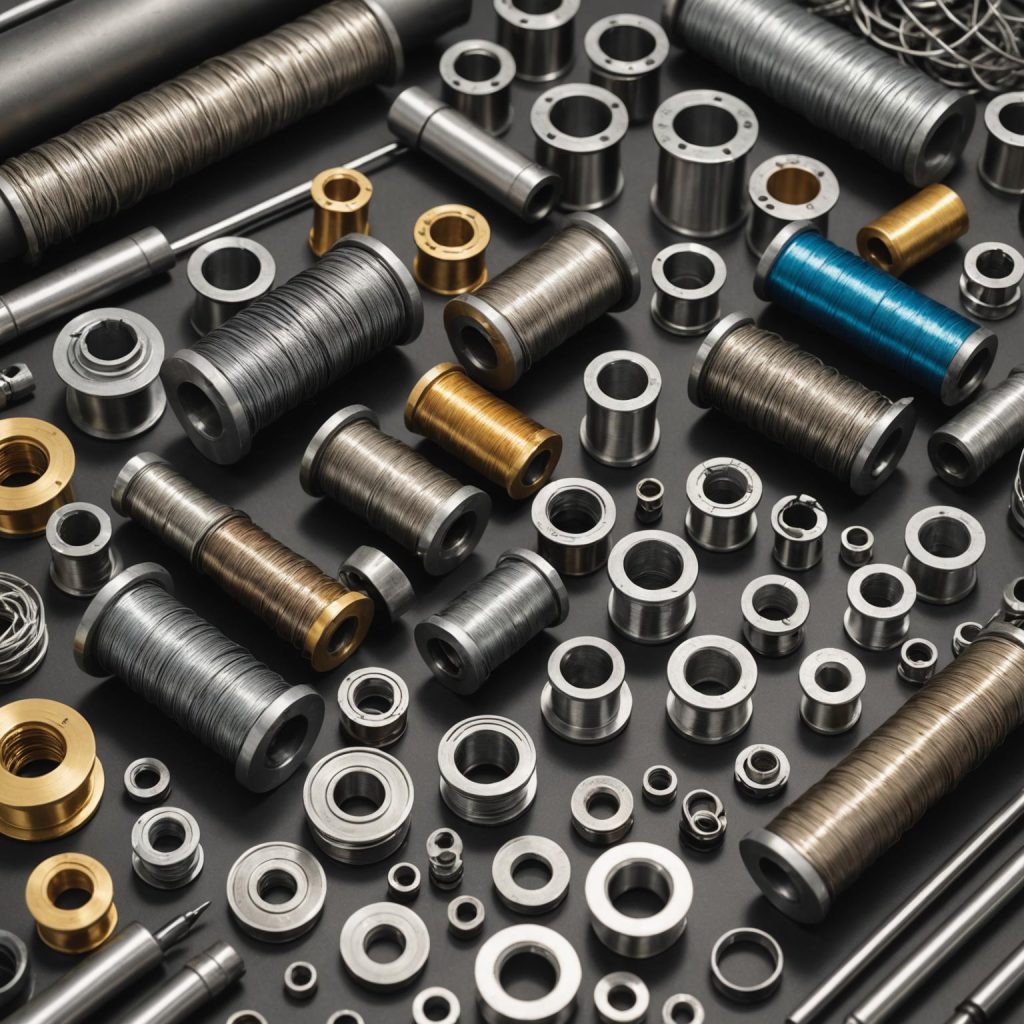

Unpacking the Superior Qualities of Titanium Filaments

The inherent characteristics of titanium render its filament forms invaluable. Its most celebrated attribute is its outstanding strength-to-weight ratio, meaning it provides the strength of steel at roughly half the weight. This makes it ideal for uses where reducing mass is crucial without compromising structural integrity. Furthermore, titanium forms a stable, protective oxide layer on its surface, granting it exceptional resistance to corrosion from saltwater, industrial chemicals, and various acidic environments. This passivation layer self-repairs if scratched, ensuring long-term durability. Another key property is its biocompatibility; the material in this wire form is non-toxic and not rejected by the human body, making it indispensable in medical implants. It also boasts a high melting point and good fatigue resistance, making high-quality titanium wire a preferred choice.

Diverse Industries Benefiting from Material Advancements

The unique blend of properties has led to widespread titanium wire applications across numerous sectors. In aerospace, it is used for critical components in aircraft and spacecraft, including fasteners, structural elements, and engine parts, where weight reduction directly translates to fuel efficiency and performance. The medical field extensively utilizes this material for surgical staples, orthodontic arches, pacemaker leads, and orthopedic pins and screws due to its biocompatibility and corrosion resistance. Marine environments, notoriously corrosive, see its use in shipbuilding, desalination plants, and offshore rigging. The chemical processing industry also benefits from its ability to withstand aggressive chemicals in reactors and piping systems.

Further Exploration of Specialized Uses

Beyond these major industries, specialized uses for titanium wire continue to emerge. For instance, in sports equipment, this high-strength filament can be found in high-performance bicycle frames, golf club heads, and tennis rackets, offering athletes an edge through lighter and stronger gear. The jewelry industry values titanium for its hypoallergenic nature, light weight, and ability to be anodized into various vibrant colors. In electronics, its non-magnetic properties and durability are beneficial. The versatility of this specific form of the metal allows for creative engineering solutions in fields ranging from robotics to high-end automotive components, pushing the boundaries of what’s possible with material science. Architects also explore its use for aesthetic and durable building elements, showcasing diverse titanium wire applications.

Key Considerations When You Procure Titanium Wire

When you decide to buy titanium wire, several factors must be considered to ensure you acquire the right product for your needs. Understanding the different grades of titanium is paramount. Commercial Pure (CP) titanium grades offer excellent corrosion resistance and formability, while alloys like Ti-6Al-4V provide higher strength. Specify the required diameter, tensile strength, surface finish, and any specific standards (e.g., ASTM, ISO) it must meet. It’s also important to discuss packaging and spooling requirements to prevent damage during transit and facilitate handling in your manufacturing process. Working with reputable sources like established titanium wire suppliers that can provide material certifications and traceability is crucial for quality assurance, especially for critical applications.

The Path Forward for Titanium-Based Solutions

The future for titanium-based solutions, particularly in filament form, looks exceptionally bright. Ongoing research aims to further enhance its properties, develop new alloys with even more specialized characteristics, and refine manufacturing processes to make it more cost-effective. As industries continue to push for lighter, stronger, and more durable materials, the utility of this specific metal filament will undoubtedly expand. Innovations in additive manufacturing (3D printing) are also opening new avenues for utilizing titanium powder and titanium wire, allowing for the creation of complex geometries previously unachievable. The commitment to sourcing from knowledgeable partners who can guide you when you next buy titanium wire will remain essential for harnessing its full potential in tomorrow’s technologies.