In the ever-advancing world of modern manufacturing, innovation and precision go hand in hand. Among the tools that revolutionize industrial processes, the **PVD coating machine** stands as a cornerstone of technological advancement. The term **PVD**, or Physical Vapor Deposition, refers to a specialized thin-film coating technique that relies on vaporized material being deposited onto a surface under vacuum conditions. This introduction not only underscores the significance of the PVD coating machine but also positions it as an indispensable asset across various industries.

### The High-Performance Vacuum Metallizing Machine: A Cutting-Edge Solution

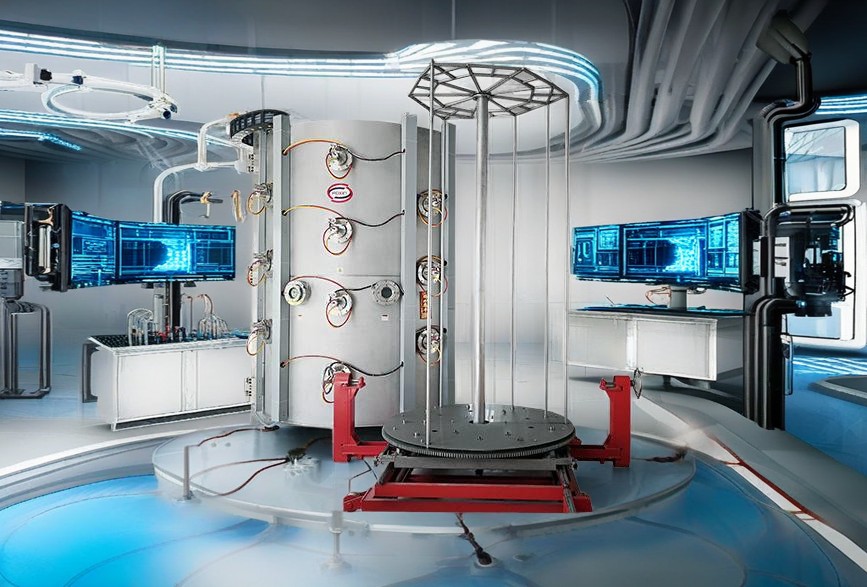

At the forefront of breakthrough coating technology is the **High-Performance Vacuum Metallizing Machine**. This groundbreaking PVD coating machine combines unparalleled efficiency, precision, and adaptability, catering to industries with demanding requirements for surface finishing excellence. Distinctively engineered for advanced applications, it seamlessly integrates form and function.

One of the most striking features of this machine is its **rotational base** mounted on a signature red chassis. This foundation ensures unmatched stability while enabling uniform and flawless rotation during the operation. Such precision in the rotational movement is critical in guaranteeing even coatings across every component. Whether the application involves small intricate parts or larger components, this design element ensures consistent results.

Adding to its versatile capabilities is the **multi-axis framework**. This innovative design accommodates a wide range of components, including bulk arrays of small items or larger, more complex parts. Its adaptable setup has made the PVD coating machine a go-to solution for industries such as automotive, aerospace, electronics, and consumer goods. The open framework promotes operator efficiency, offering ease of loading and unloading while maintaining the machine’s structural integrity during even the most demanding cycles.

### The Advantages of PVD Coating and Vacuum Metallizing

With the advanced **cylindrical vacuum chamber** at the core of its design, the High-Performance Vacuum Metallizing Machine is all about delivering superior results. The chamber is equipped with **multi-point gas inlets**, allowing for optimal distribution of metal vapor during the metallization process. This intelligent design is accompanied by a precisely calibrated vacuum pump system, ensuring operators have full control over pressure, temperature, and deposition rates. This level of control ensures the ultimate adhesion and uniformity of coatings, which is critical for meeting stringent quality standards.

Operating such a system demands exceptional cooling and power infrastructures. Along the vertical axis of the chamber, an array of **cooling systems and power conduits** work in harmony to ensure stability during high-speed production cycles. These components are integrated seamlessly, prioritizing safety, efficiency, and durability. As a bonus, they lend the machine a visually futuristic, industrial aesthetic.

One of the greatest strengths of PVD coating is its ability to create stunning, high-performance surfaces that are not only aesthetically appealing but also highly durable. From high-reflectivity coatings that rival chrome finishes to wear-resistant layers that extend the lifespan of tools, PVD coatings open the door to countless applications. Whether it is creating automotive luxury accents, advanced aerospace parts, or wearable electronics components, the PVD coating machine delivers excellence every time.

### The Technological Edge: Real-Time Monitoring and Control

What sets this PVD coating machine apart is its integration of **smart control interfaces**, embodying the principles of Industry 4.0. This technological sophistication allows operators to harness real-time monitoring and make adjustments with pinpoint accuracy. The days of labor-intensive manual calibration are a thing of the past, as modern software automates critical aspects of the metallization process.

The **AI-powered interface** acts as a co-pilot, ensuring consistent, flawless results throughout each cycle. Parameters such as substrate temperature, vacuum pressure, and deposition rates can be monitored and adjusted in real time, enabling unparalleled precision and reliability. This innovative control system ensures that even the most challenging coatings are executed to perfection, helping manufacturers achieve consistent product quality.

### A Versatile Tool for a Range of Industries

The adaptability of the High-Performance Vacuum Metallizing Machine makes it a vital asset across numerous sectors. One of its primary applications includes the automotive domain, where it is used to deposit shimmering, chrome-like finishes on vehicle parts and accents. This type of metallic coating not only enhances a vehicle’s aesthetic appeal but also adds a layer of protection to the components.

In the field of electronics, PVD coating plays a pivotal role in producing wear-resistant layers on components such as semiconductor devices, printed circuit boards, and even casings for consumer electronics. The precision of this machine ensures that even the smallest and most intricate parts are coated evenly and effectively.

The aerospace and defense industries also rely on PVD coating machines for producing highly durable and functional coatings. From aerospace-grade turbine blades to lightweight structural components, the technology ensures these critical parts perform reliably under extreme operating conditions. The adaptability and precision of such a coating system make it the perfect choice for cutting-edge innovation.

### The Future of Manufacturing with PVD Coating Machines

As industries push the boundaries of what is possible, technologies like the PVD coating machine pave the way for extraordinary advancements. Machines like the **High-Performance Vacuum Metallizing Machine** demonstrate how innovation, efficiency, and precision come together to create superior solutions for complex manufacturing challenges. The ability to produce coatings that combine aesthetic beauty with resilience and functionality redefines the standards of surface finishing technology.

Moreover, the environmentally friendly nature of the PVD process is worth noting. Unlike traditional coating methods, which often involve harmful chemicals and generate significant waste, PVD is a cleaner and more sustainable option. With global industries prioritizing green manufacturing, the adoption of PVD technology aligns perfectly with future trends.

In conclusion, the **PVD coating machine** is more than just a piece of industrial equipment—it is a revolutionary force in modern manufacturing. With its state-of-the-art design and expansive capabilities, the High-Performance Vacuum Metallizing Machine ensures producers stay at the cutting edge of their industries. Whether you are in the automotive, aerospace, electronics, or consumer goods sector, this advanced machinery offers the perfect blend of functionality, efficiency, and aesthetic output. It is not just about coating surfaces; it is about setting new benchmarks of excellence for generations to come.

评价

Clear filters目前还没有评价